Products

Contact Information

Address: China (Boye) conveyor belt Industrial zone

Telephone:+86 18395653111

Mailbox:colin@bestbelting.com

Aramid conveyor belt

Keyword:

Aramid conveyor belt

1. uses

Aramid conveyor belts combine high strength, lightweight materials with multi-functional cover materials, making the product perfectly suitable for a variety of applications.

2. features

low energy consumption

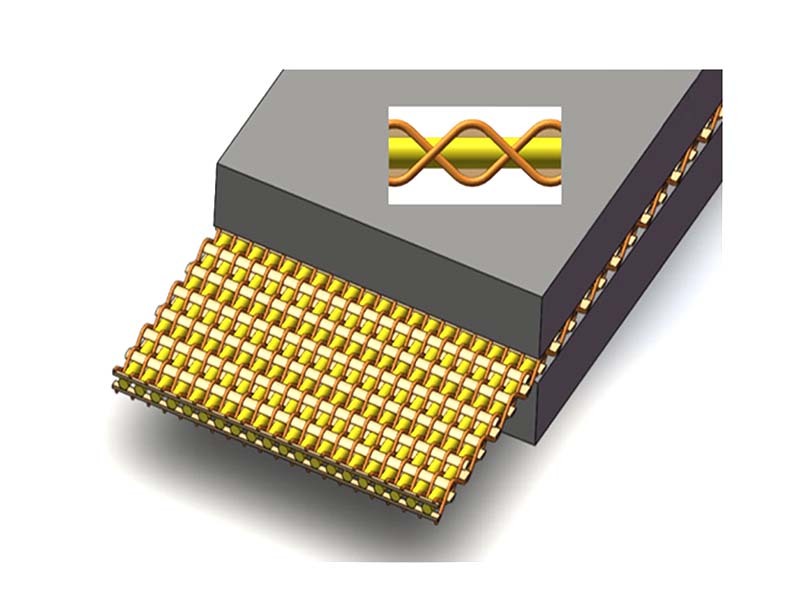

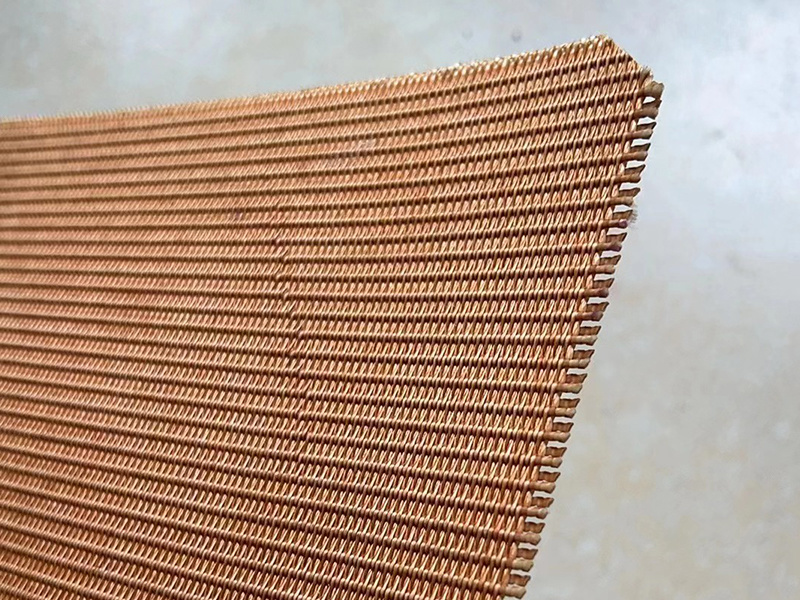

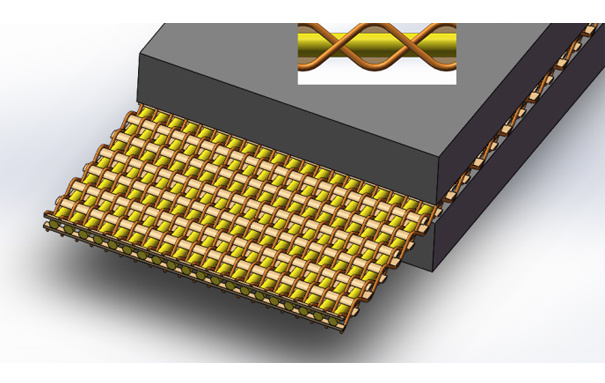

The straight warp and straight weft structure is composed of warp aramid cords and horizontal nylon cords for protection on both sides. The lightweight double Wrigley aramid conveyor belt can reduce the power consumption of the conveyor. The use of low rolling resistance energy-saving rubber as a non-working surface can achieve higher consumption reduction.

Impact resistance

Due to the strong aramid fiber can prevent the conveyor belt by sharp transport puncture, even high drop distance, can also reduce the damage of the conveyor belt.

High heat resistance and fire resistance

High heat resistance prevents damage by high-temperature transports, and even burning objects are difficult to penetrate the aramid core.

Anti-corrosion

Aramid itself has excellent medium resistance, and has good chemical resistance and corrosion resistance.

Optimized belt design, long service life

Since the belt body is a single layer design, the belt body is soft and light, has ideal strength utilization, and is very fatigue resistant during the entire service life. The upper cover glue and the lower cover glue meet the high requirements for wear resistance and impact resistance, and provide ideal protection for high-value aramid fabrics.

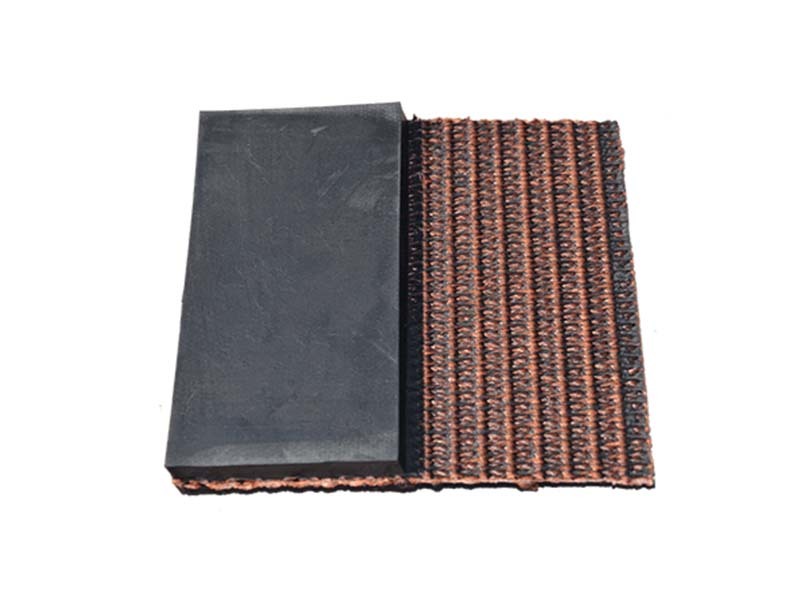

3. standard structure

4. product specifications

| Specifications | Minimum longitudinal tensile strength (N/mm) |

Minimum transverse tensile strength (N/mm) |

10% load elongation (max.) |

Covering glue standard mm |

Conveyor belt thickness mm |

Conveyor belt weight Kg/m2 |

| DPP800 | 800 | 150 | 0.5 | 6 2 | 11.5 | 11.0 |

| DPP1000 | 1000 | 150 | 0.5 | 6 2 | 11.5 | 11.1 |

| DPP1250 | 1250 | 150 | 0.5 | 6 2 | 11.6 | 11.3 |

| DPP1600 | 1600 | 180 | 0.5 | 6 3 | 12.0 | 12.9 |

| DPP1800 | 1800 | 180 | 0.5 | 6 3 | 12.3 | 13.1 |

| DPP2000 | 2000 | 180 | 0.5 | 6 3 | 14.5 | 15.9 |

| DPP2250 | 2250 | 180 | 0.5 | 6 3 | 14.5 | 16.1 |

| DPP2500 | 2500 | 200 | 0.5 | 6 3 | 14.6 | 16.3 |

| DPP3150 | 3150 | 200 | 0.5 | 6 3 | 16.3 | 17 |

5. cover glue level

According to ISO15236-2016 standard requirements:

| Type | Tensile strength (ISO37) Mpa |

Elongation at break (ISO37) % |

Abrasion (ISO4649) mm3 |

| H | 24 | 450 | 120 |

| D | 18 | 400 | 100 |

| L | 15 | 350 | 200 |

| K2 | 15 | 350 | 200 |

| Note: K2For a general flame retardant and antistatic tape, in line with ISO340 and ISO284 standards. | |||

| German Standard DIN-22102 | ||||||

| Grade | Tensile strength ≥ Ma | Elongation at break ≥ M% | Abrasion ≥ mm3 | Adhesion strength between layers of cloth (N/mm) | Adhesion strength between cover layer and cloth layer (/mm) | |

| Covering layer thickness 0.8~1.5mm | Cover layer thickness> 1.5mm | |||||

| W | 18 | 400 | 90 | ≥ 5 | 3.5 | 4.5 |

| X | 25 | 450 | 120 | |||

| Y | 20 | 400 | 150 | |||

| Z | 15 | 350 | 250 | |||

| English Standard BS 490 | ||||||

| Grade | Tensile strength ≥ Ma | Elongation at break ≥ M% | Abrasion ≥ mm3 | Adhesion strength between layers of cloth (N/mm) | Adhesion strength between cover layer and cloth layer (/mm) | |

| Covering layer thickness 0.8~1.5mm | Cover layer thickness> 1.5mm | |||||

| M | 24 | 450 | - | ≥5.25 | 3.15 | 4.5 |

| N | 17 | 400 | - | |||

| Australian Standard AS 1332-2000 | ||||||

| Grade | Tensile strength ≥ Ma | Elongation at break ≥ M% | Abrasion ≥ mm3 | Adhesion strength between layers of cloth (N/mm) | Adhesion strength between cover layer and cloth layer (/mm) | |

| Covering layer thickness 0.8~1.5mm | Cover layer thickness> 1.5mm | |||||

| A | 17 | 400 | 70 | 6 | 4 | 4.8 |

| E | 14 | 300 | - | |||

| F | 14 | 300 | - | |||

| M | 24 | 450 | 125 | |||

| N | 17 | 400 | 200 | |||

| S | 14 | 300 | 250 | |||

| S* | 12 | 300 | 250 | |||

| South Africa SANS 1173:2005 | ||||||

| Grade | Tensile strength ≥ Ma | Elongation at break ≥ M% | Abrasion ≥ mm3 | Adhesion strength between layers of cloth (N/mm) | ||

| Adhesive strength between cover layer and cloth layer (N/mm) | ||||||

| A | 18 | 400 | 90 | ≥ 7 | ≥ 5 | |

| X | 25 | 450 | 120 | |||

| M | 24 | 450 | 150 | |||

| N | 20 | 400 | 250 | |||

Specification and Technical Parameters of Nylon Multilayer Fabric Core Conveyor Belt

| Fabric Type | Fabric construction | Fabric type | Thickness of adhesive tape (mm/p) | Strength series (N/mm) | Cover glue thickness | Width range (mm) | ||||||

| By | Weft | Layer 2 | Layer 3 | 4 floors | 5 floors | 6 layers | Upper covering layer | Lower cover | ||||

| Nylon | cotton nylon | cotton nylon | Nn-100 | 1.00 | 200 | 300 | 400 | 500 | 600 | 0-12 | 0-10 | 300-2500 |

| Nn-125 | 1.05 | 250 | 375 | 500 | 625 | 750 | ||||||

| Nn-150 | 1.10 | 300 | 450 | 600 | 750 | 900 | ||||||

| Nn-200 | 1.20 | 400 | 600 | 800 | 1000 | 1200 | ||||||

| Nn-250 | 1.40 | 500 | 750 | 1000 | 1250 | 1500 | ||||||

| Nn-300 | 1.60 | 600 | 900 | 1200 | 1500 | 1800 | ||||||

Adhesive strength, elongation performance in accordance with the following table

| Adhesion strength, elongation performance | |||||

| Core material | bond strength | Extension performance | |||

| Interlayer N/mm | Covering layer and layer N/mm | Full thickness longitudinal elongation at break | Full thickness longitudinal reference force elongation | ||

| Covering layer thickness ≤ 1.5mm | Covering layer thickness ≥ 1.5mm | ||||

| Polyester Canvas | ≥ 5 | ≥ 4.5 | ≥ 5 | ≥ 10% | ≤ 4% 6 |

The covering performance of the tape is in accordance with the following table

| Covering performance of tape | |||||

| Overlay Level | Tensile strength | Elongation at break | Abrasion | Change rate of tensile strength and elongation at break after aging | |

| Mpa | Kgf/cm2 | % | mm3 | % | |

| H | ≥ 24 | ≥ 240 | ≥ 450 | ≤ 120 | -25~ 25 |

| D | ≥ 18 | 180 | ≥ 400 | ≤100 | -25~ 25 |

| L | ≥ 15 | 150 | ≥ 350 | ≤200 | -25~ 25 |

FAQ

Characteristics of Polyester Conveyor Belt

High modulus, low elongation, good heat stability, impact resistance and other characteristics, suitable for medium and long distance, high-speed, high-speed conditions of conveying materials.

Body material for heat-resistant conveyor belts

The subject material of the heat-resistant conveyor belt includes a skeleton material, a covering layer and a base material.

Selection of the diameter of the conveying roller

The selection of roller diameter should consider the following factors: the average specific pressure between the conveyor belt and the roller surface, the amount of deformation of the bag and the bag, the utilization rate of the allowable strength of the conveyor belt, the frequency of bending of the conveyor belt, the installation location of the conveyor and the conditions of use.

Main material of nylon conveyor belt

The main material of the nylon conveyor belt is nylon, but it does not have enough tension, so it is necessary to add a layer of industrial polyester cloth between nylon and nylon to increase the tension when making the finished product.

The advantages of the pattern conveyor belt

The pattern conveyor belt can ensure the smooth transportation of materials, with anti-skid, impact resistance, and high temperature resistance.

Related Products

Product inquiry

To: Baoding Fangnuo Rubber Products Manufacturing Co., Ltd.