Products

Contact Information

Address: China (Boye) conveyor belt Industrial zone

Telephone:+86 18395653111

Mailbox:colin@bestbelting.com

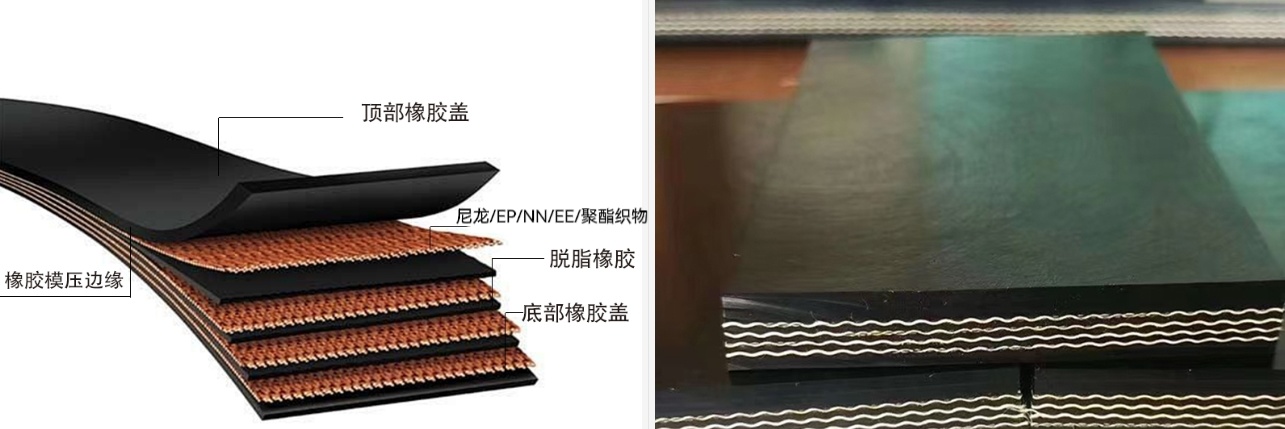

High wear-resistant energy-saving multi-layer fabric core conveyor belt

Keyword:

High wear-resistant energy-saving multi-layer fabric core conveyor belt

Details

Uses

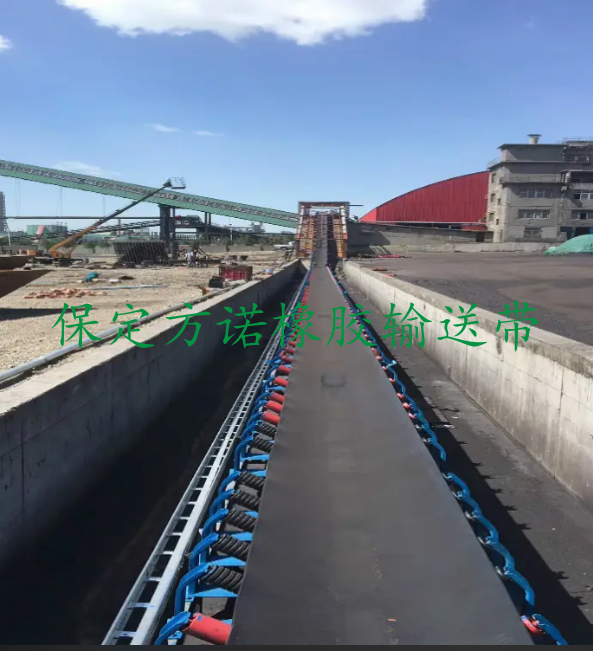

High wear-resistant and energy-saving multi-ply fabric core conveyor belts are especially suitable for mining, stone crushing and screening, sand washing, ports and docks, power, metallurgy, chemical, coal, steel plants, cement plants, construction and other industries. They are suitable for most medium/long distances, high loads, and high-speed material conveying conditions.

Features

1. Energy-saving: Improves rubber elasticity and reduces transmission friction coefficient, saving 10%-15% of electricity.

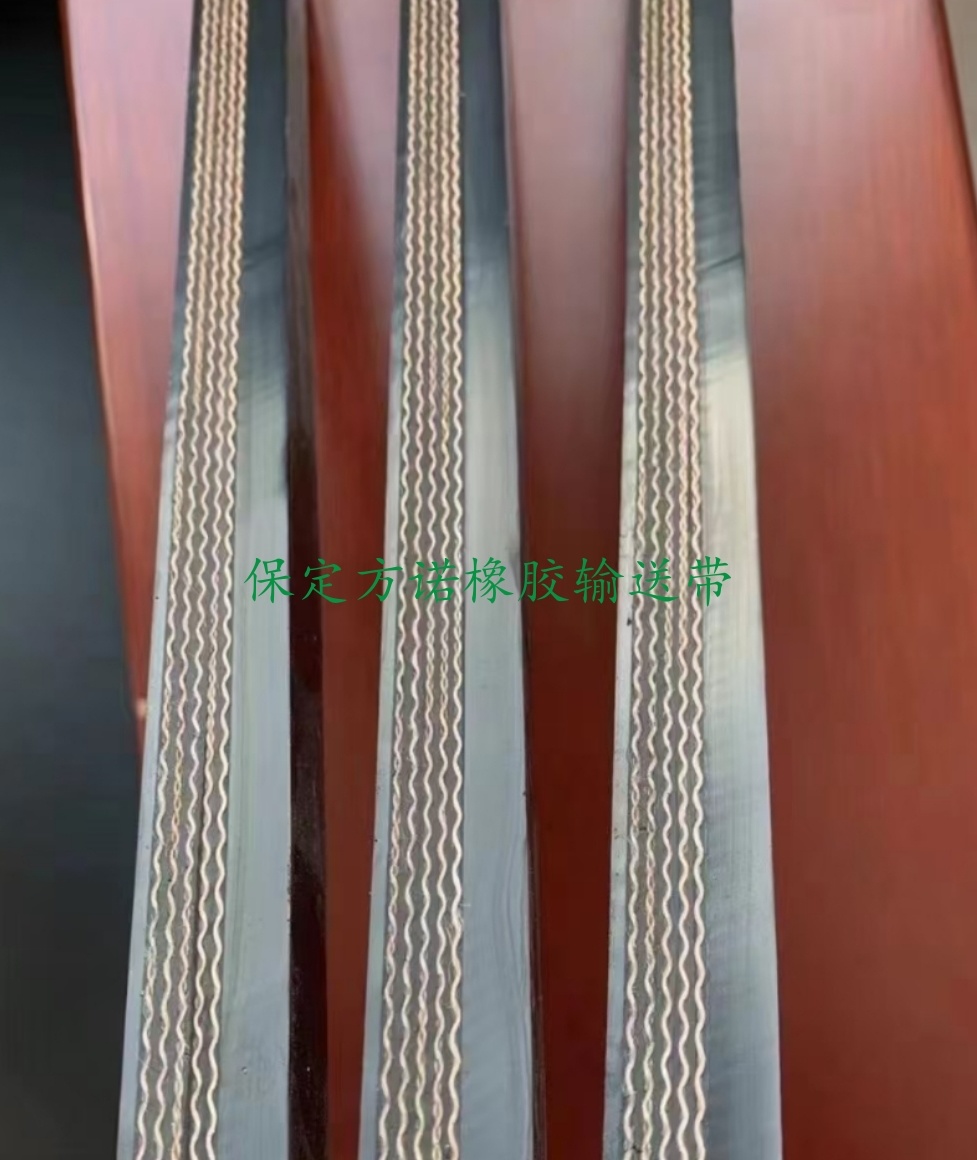

2. Wear-resistant: The surface coating has high elasticity, good wear resistance, high strength, excellent fatigue resistance, high strength, impact resistance, good belt troughing, large bonding force of multi-ply fabric core, and long service life.

3. Types: Can produce heavy-duty multi-ply fabric core conveyor belts with high tensile strength, general-purpose/wear-resistant/oil-resistant/heat-resistant/cold-resistant/acid and alkali-resistant/flame-retardant/anti-static types.

4. Specifications: This is a multi-ply fabric core rubber conveyor belt made of (nylon/EP/NN/EE/polyester) fabric core structured weft and warp yarns and SBR/NBR/EPDM rubber. We are a manufacturer of heavy-duty industrial fabric rubber conveyor belts. This fabric core conveyor belt is known for its unique features: high strength resistance, fatigue resistance, wear resistance, durability, and energy saving. It meets the needs of medium/long distance transportation under various industrial and mining conditions, and it is used in most industries.

Application Areas

Our multi-ply fabric rubber conveyor belts are especially suitable for the mining, chemical fertilizer, power, cement plants, steel plants, metallurgy, coal, grain, chemical, port, and construction industries, suitable for most short/medium/long distances, high loads, and high-speed material conveying conditions.

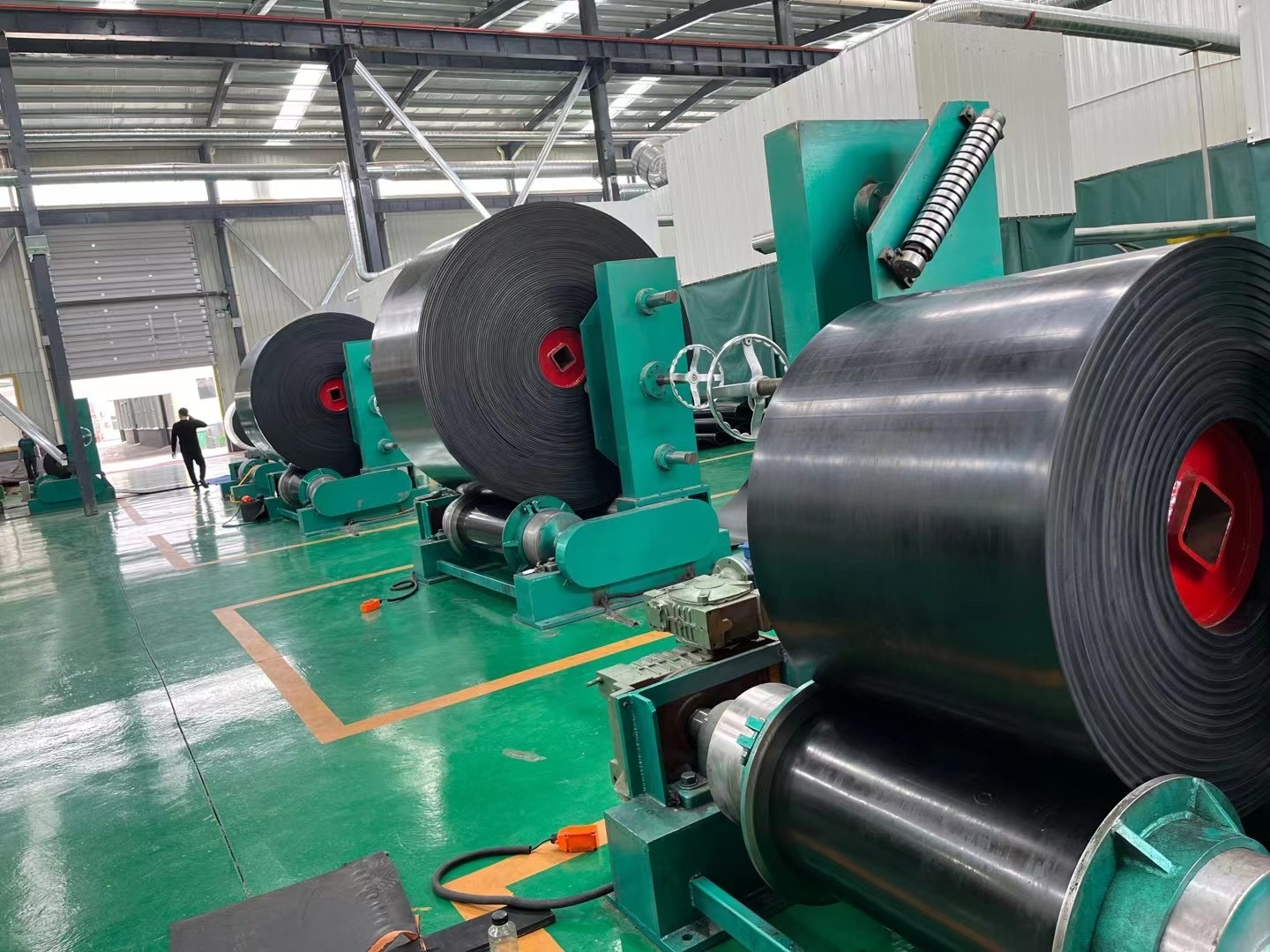

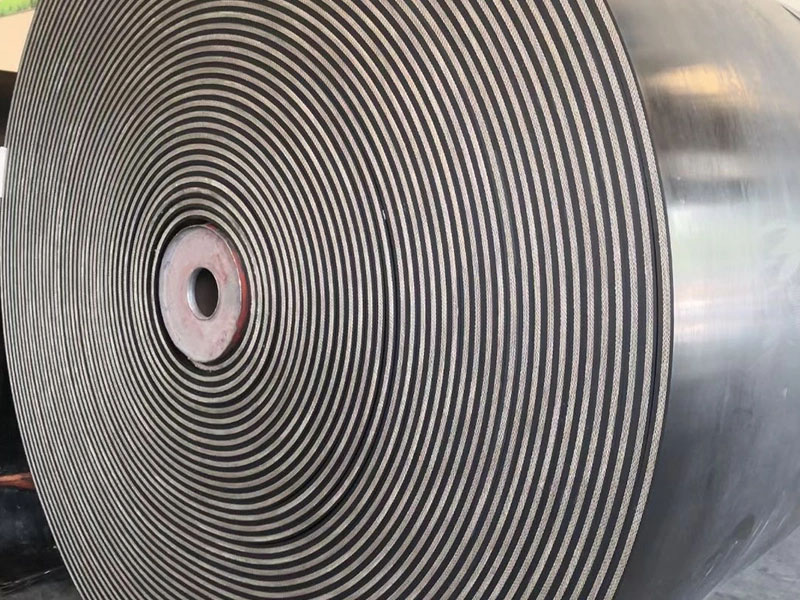

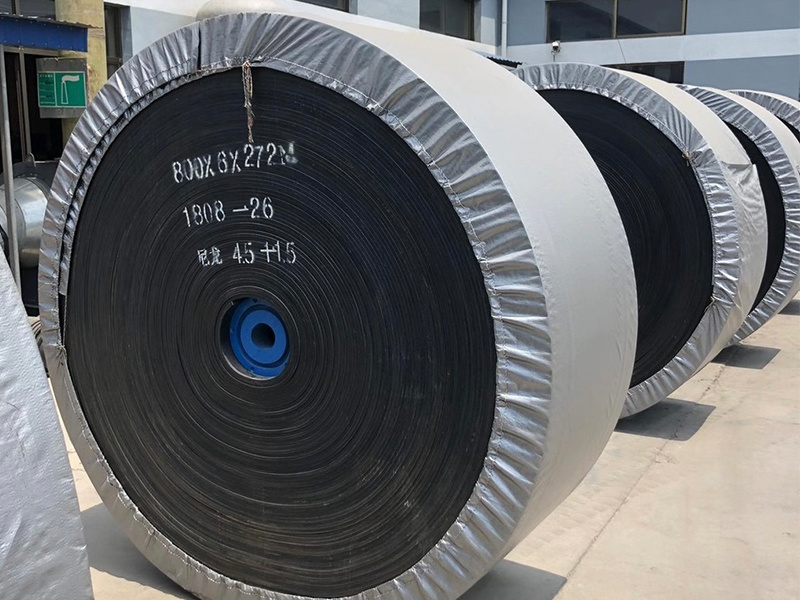

Product Pictures

|

|

|

Specifications and Technical Data

| Fabric Type | Fabric Structure | Fabric Specifications | Thickness | Strength (N/mm ) | Cover Thickness | Width | Length | |||||

| Warp | Weft | mm/ply | 2ply | 3Ply | 4ply | 5ply | Top | Bottom | mm | m | ||

| Polyester Fiber

Nylon

EP

NN

EE |

Post | Polyamine | EP80 | 0.95 | 160 | 240 | 320 | 400 |

1.5-12 |

0-4.5 |

400-2500 | 50-500 |

| EP100 | 1 | 200 | 300 | 400 | 500 | |||||||

| EP150 | 1.1 | 300 | 450 | 600 | 750 | |||||||

| EP200 | 1.2 | 400 | 600 | 800 | 1000 | 500-2500 | ||||||

| EP250 | 1.35 | 500 | 7500 | 1000 | 1250 | |||||||

| EP300 | 1.45 | 600 | 900 | 1200 | 1500 | |||||||

| EP350 | 1.6 | - | 1050 | 1400 | 1750 | 800-2500 | ||||||

| EP400 | 1.75 | - | - | 1600 | 2000 | 1000-2500 | ||||||

| EP500 | 1.9 | - | - | 2000 | 2500 | |||||||

| EP630 | 2.1 | - | - | 2400 | 3000 | |||||||

Conveyor Belt Adhesion and Elongation

| Bonding Strength | Elongation | |||

| Between plies (N/mm ) | Between rubber | Longitudinal elongation when %≥ | Longitudinal elongation at 6s reference load % | |

| EP Conveyor Belt | ≥5 | ≥5 | 10 | 2 |

Cover Rubber Grade

| Cover Grade | Tensile Strength | Elongation | Wear | Tensile Strength and Elongation after Aging | Standard |

| ≥ | ≥ | ≤ | |||

| MPA | % | MM3 | % | ||

| M | 24 | 450 | 125 | -50 | Australian Standard AS1332-2000 |

| N | 17 | 400 | 200 | -50 | |

| RMA1 | 17 | 400 | 175 | -50 | American Standard |

| RIMA2 | 14 | 350 | 250 | -50 | |

| Z | 15 | 350 | 250 | -50 | German Standard DIN22102 |

| Y | 20 | 400 | 150 | -50 | |

| X | 25 | 400 | 120 | -50 | |

| W | 18 | 400 | 90 | -50 | |

| C | 10 | 150 | 200 | -50 | Russian Standard |

| N | 15 | 400 | 100 | -50 | |

| T2 | 14.7 | 300 | 200 | -50 | |

| M | 14.7 | 350 | 150 | -50 |

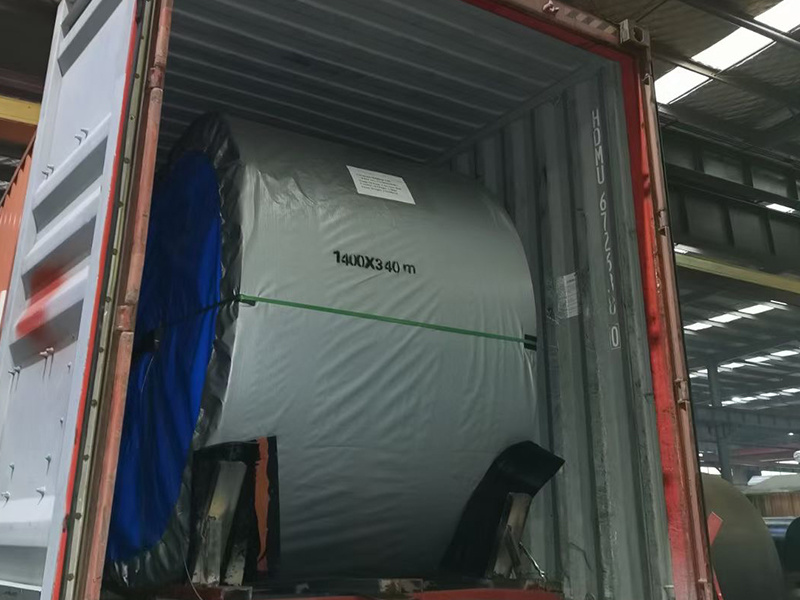

Packaging and Transportation

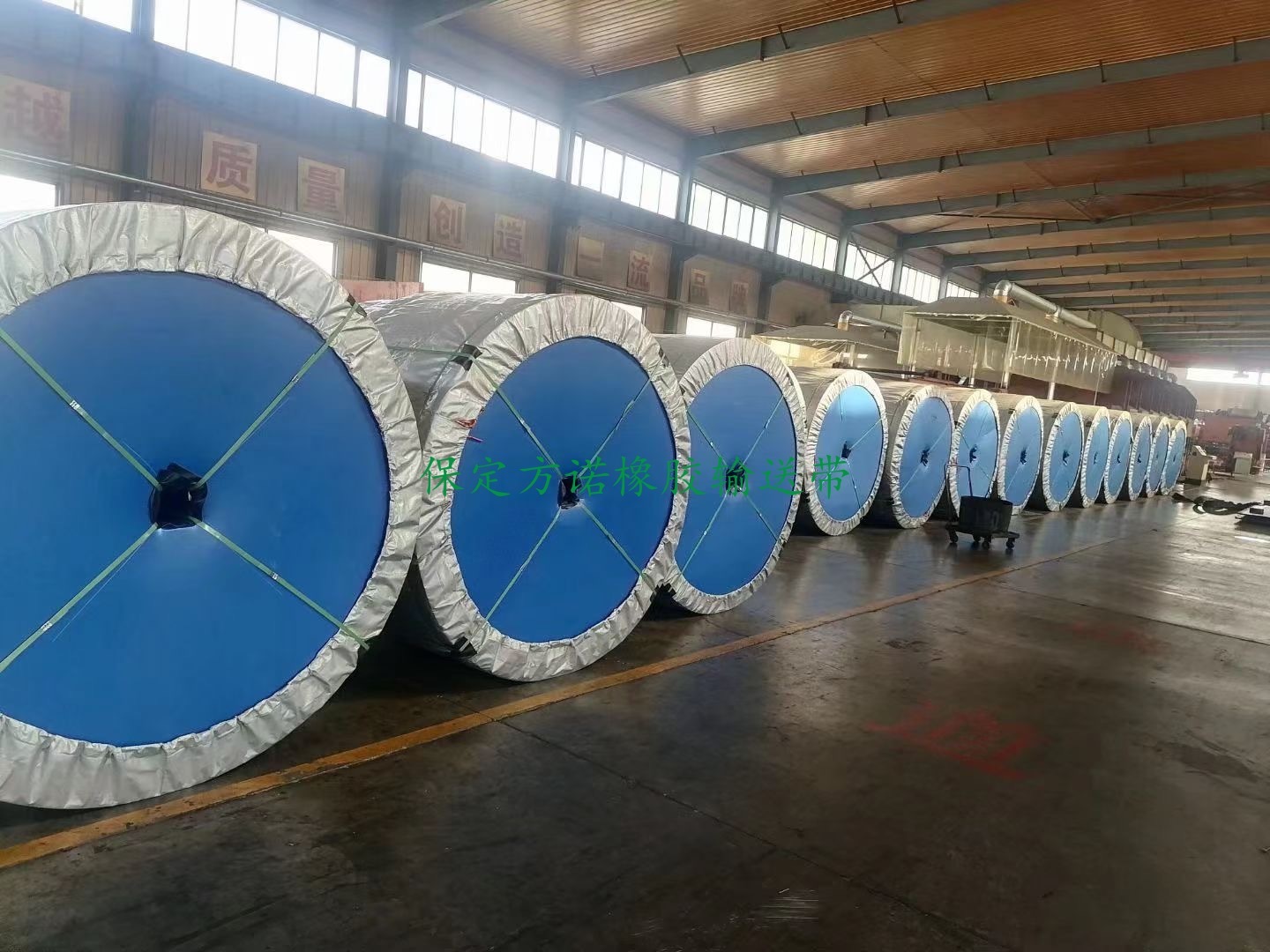

|

|

|

|

Packaging Details

1. Waterproof nylon packaging, with bottom steel pallet or wooden pallet.

2. Standard and suitable export packaging.

3. Customized packaging is available according to customer requirements.

Why Choose Our Conveyor Belts?

1. Engineering Design and Consulting

FANGNUO Rubber Conveyor Belt is one of the best custom belt manufacturers in China. Our conveyor belts are well-suited for bulk material handling of various heavy and abrasive materials, successfully meeting the needs of various industries including stone crushing and screening, sand washing, fertilizer and grain conveying, steel plants, power plants, cement plants, metallurgy, coal, ports and docks, and construction. As a one-stop conveyor engineering manufacturer, we also provide excellent solutions to material conveying problems and after-sales service for various applications.

2. Excellent Customer Service

We specialize in the production of heavy-duty (nylon, EP, EE, NN, polyester) multi-ply fabric core rubber conveyor belts, steel wire rope core conveyor belts, corrugated edge conveyor belts, bucket elevator conveyor belts, herringbone conveyor belts, circular conveyor belts, etc. As a leading Chinese manufacturer, supplier, and exporter of high-quality conveyor belts, we are committed to providing our customers with superior products and professional services. Fang Nuo Company has grown rapidly through innovation and professional service, and we are eager to expand our domestic and international markets!

3. Customization

We support OEM and can meet all your needs, regardless of scale. Even if you only have an idea, we can help you bring it to life.

We have a strong R&D team that can develop and produce products based on customer-provided drawings or samples.

4. Cost-effectiveness

Same quality, lower price; same price, higher quality. Fast production cycle, short lead times, high efficiency, durability, and reliable quality. We focus on the mid-to-high-end market, and our products meet international standards.

FAQ

Characteristics of Polyester Conveyor Belt

High modulus, low elongation, good heat stability, impact resistance and other characteristics, suitable for medium and long distance, high-speed, high-speed conditions of conveying materials.

Body material for heat-resistant conveyor belts

The subject material of the heat-resistant conveyor belt includes a skeleton material, a covering layer and a base material.

Selection of the diameter of the conveying roller

The selection of roller diameter should consider the following factors: the average specific pressure between the conveyor belt and the roller surface, the amount of deformation of the bag and the bag, the utilization rate of the allowable strength of the conveyor belt, the frequency of bending of the conveyor belt, the installation location of the conveyor and the conditions of use.

Main material of nylon conveyor belt

The main material of the nylon conveyor belt is nylon, but it does not have enough tension, so it is necessary to add a layer of industrial polyester cloth between nylon and nylon to increase the tension when making the finished product.

The advantages of the pattern conveyor belt

The pattern conveyor belt can ensure the smooth transportation of materials, with anti-skid, impact resistance, and high temperature resistance.

Related Products

Product inquiry

To: Baoding Fangnuo Rubber Products Manufacturing Co., Ltd.