Products

Contact Information

Address: China (Boye) conveyor belt Industrial zone

Telephone:+86 18395653111

Mailbox:colin@bestbelting.com

Belt joint vulcanizer

Keyword:

Belt joint vulcanizer

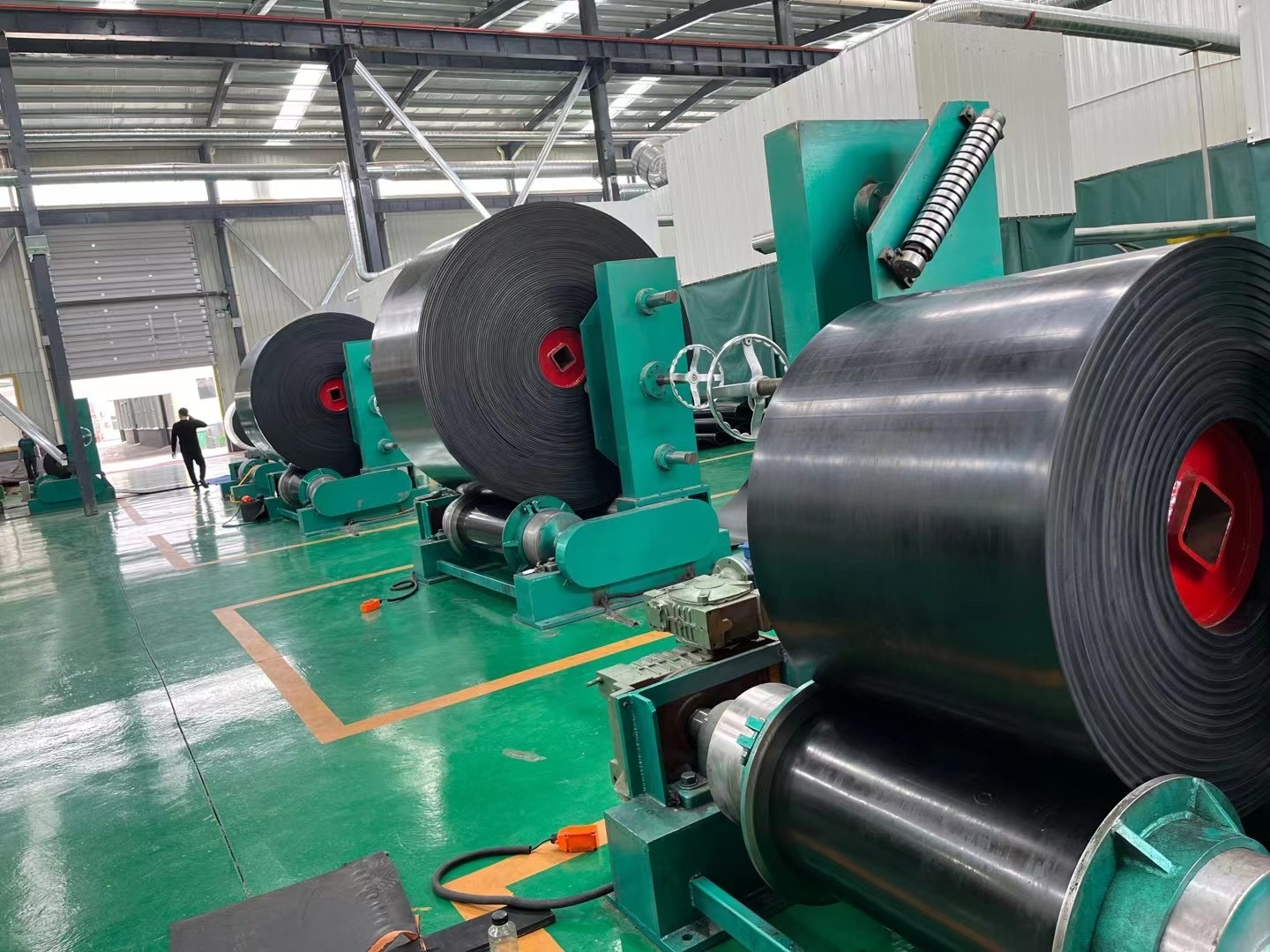

Belt joint vulcanizer is mainly used for the connection and repair of conveyor belt joints. Its working principle is to vulcanize the joint part of the conveyor belt by heating and pressurizing, so as to form a firm connection.

Belt joint vulcanizer has high accuracy and stability. It can accurately control temperature and pressure to ensure the smooth progress of the vulcanization process and the reliability of the joint quality. The advanced temperature control system can ensure uniform heating and avoid local overheating or insufficient temperature.

Its compact design is easy to carry and operate, and can adapt to different working environments and site conditions. Whether in the factory workshop or at the outdoor construction site, it can play an excellent performance.

Belt Joint Vulcanizer plays a key role in the maintenance and replacement of conveyor belts. It can complete the joint vulcanization work quickly and efficiently, greatly shortening the downtime and improving production efficiency.

At the same time, the durability of Belt joint vulcanizer is also excellent. Made of high-quality materials and exquisite craftsmanship, it can withstand long-term use and various harsh environments.

In addition, it is also easy to operate. Operators only need simple training to master its use and complete the vulcanization operation easily.

FAQ

Characteristics of Polyester Conveyor Belt

High modulus, low elongation, good heat stability, impact resistance and other characteristics, suitable for medium and long distance, high-speed, high-speed conditions of conveying materials.

Body material for heat-resistant conveyor belts

The subject material of the heat-resistant conveyor belt includes a skeleton material, a covering layer and a base material.

Selection of the diameter of the conveying roller

The selection of roller diameter should consider the following factors: the average specific pressure between the conveyor belt and the roller surface, the amount of deformation of the bag and the bag, the utilization rate of the allowable strength of the conveyor belt, the frequency of bending of the conveyor belt, the installation location of the conveyor and the conditions of use.

Main material of nylon conveyor belt

The main material of the nylon conveyor belt is nylon, but it does not have enough tension, so it is necessary to add a layer of industrial polyester cloth between nylon and nylon to increase the tension when making the finished product.

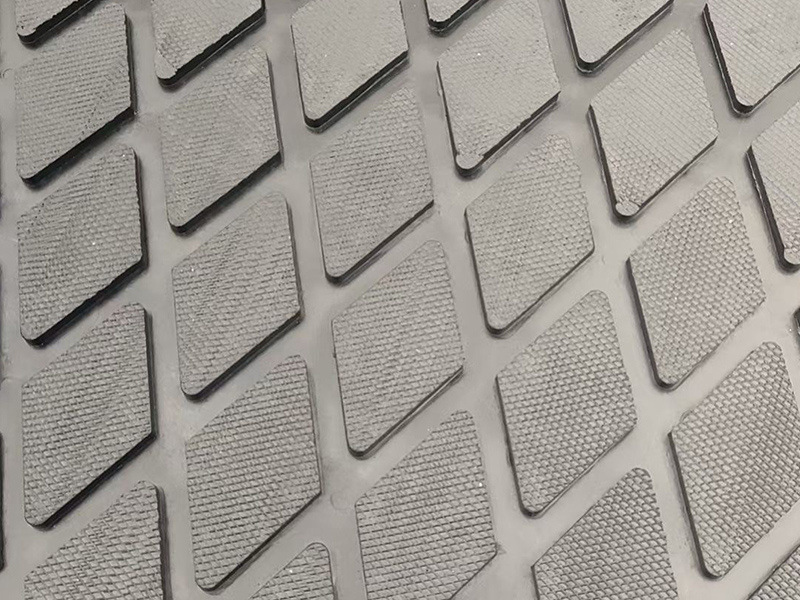

The advantages of the pattern conveyor belt

The pattern conveyor belt can ensure the smooth transportation of materials, with anti-skid, impact resistance, and high temperature resistance.

Related Products

Product inquiry

To: Baoding Fangnuo Rubber Products Manufacturing Co., Ltd.