Products

Contact Information

Address: China (Boye) conveyor belt Industrial zone

Telephone:+86 18395653111

Mailbox:colin@bestbelting.com

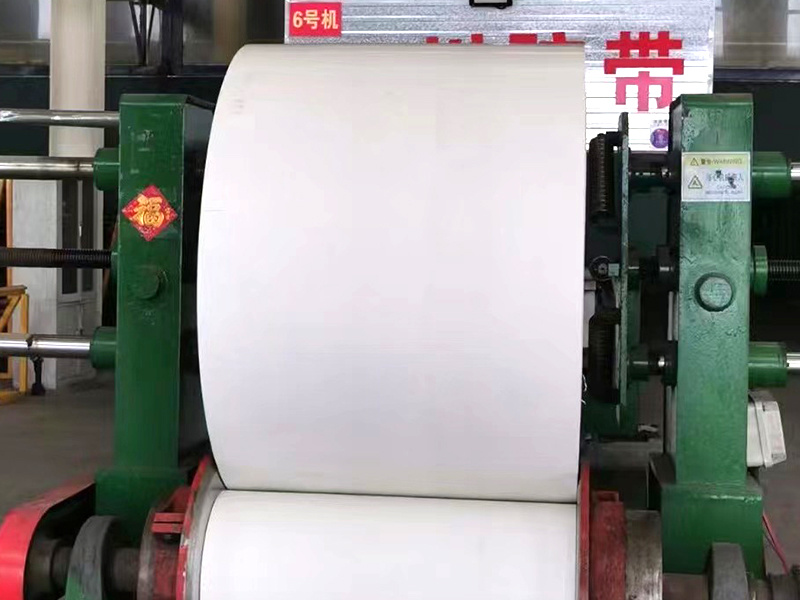

china White conveyor belt

Keyword:

china White conveyor belt

1. definition and use

The white conveyor belt is usually defined as a food conveyor belt, which is mainly used in the food industry or the food sector to transport bulk grain, grain and oil, poultry, meat processing and other related products. In addition, it is also widely used in industries such as medicine, cosmetics, packaging, electronics, automobiles and logistics.

2. features and advantages

Hygiene: The white conveyor belt is designed and processed with a special formula, which meets the hygiene standards, can ensure the hygiene of food, and at the same time meet the sterile requirements of the pharmaceutical, cosmetics and other industries.

Wear resistance and corrosion resistance: it has excellent wear resistance, corrosion resistance and oil resistance, can resist the erosion of various corrosive substances and grease, and prolong the service life.

Easy to clean: The surface of the white conveyor belt is smooth, not easy to adhere to impurities and dirt, easy to clean and disinfect, and keep the working environment clean.

High tensile strength: the belt core is made of excellent fabric, with high tensile strength, no deformation and no shrinkage, ensuring the stability and reliability in the conveying process.

3. classification and specification

White conveyor belt according to the material can be divided into PVC white conveyor belt, ordinary chemical with white rubber conveyor belt and rubber conveyor belt three. According to the different use environment, it can also be divided into high temperature resistance, heat resistance, cold resistance, oil resistance, acid and alkali resistance, flame retardant, anti-static and other different specifications. The production width can reach more than 6 meters to meet the needs of different occasions.

4. Application Areas

Food processing industry: used to transport food raw materials, processed products and packaging materials, etc., to ensure food hygiene and.

Pharmaceutical industry: used in pharmaceutical production line delivery of drugs, medicine bottles, powder, etc., in line with health standards, easy to clean and disinfect.

Cosmetics and personal care products industry: production lines used to transport various cosmetics and personal care products, such as shampoo, perfume, shower gel, etc., to maintain the purity and sterility of the products.

Packaging industry: used to transport cartons, plastic bottles, glass bottles and other packaging materials, with good wear resistance and corrosion resistance.

Electronics industry: used in the manufacturing process of electronic products, such as semiconductor, battery, display and other production lines to ensure dust-free and electrostatic protection of products.

Automotive industry: used for conveying parts and finished products on the automobile assembly line, with high wear resistance and strength.

Logistics industry: used in various logistics scenarios, such as freight, warehousing, etc., to transport goods and packaging materials.

| German Standard DIN-22102 | ||||||

| Grade | Tensile strength ≥ Ma | Elongation at break ≥ M% | Abrasion ≥ mm3 | Adhesion strength between layers of cloth (N/mm) | Adhesion strength between cover layer and cloth layer (/mm) | |

| Covering layer thickness 0.8~1.5mm | Cover layer thickness> 1.5mm | |||||

| W | 18 | 400 | 90 | ≥ 5 | 3.5 | 4.5 |

| X | 25 | 450 | 120 | |||

| Y | 20 | 400 | 150 | |||

| Z | 15 | 350 | 250 | |||

| English Standard BS 490 | ||||||

| Grade | Tensile strength ≥ Ma | Elongation at break ≥ M% | Abrasion ≥ mm3 | Adhesion strength between layers of cloth (N/mm) | Adhesion strength between cover layer and cloth layer (/mm) | |

| Covering layer thickness 0.8~1.5mm | Cover layer thickness> 1.5mm | |||||

| M | 24 | 450 | - | ≥5.25 | 3.15 | 4.5 |

| N | 17 | 400 | - | |||

| Australian Standard AS 1332-2000 | ||||||

| Grade | Tensile strength ≥ Ma | Elongation at break ≥ M% | Abrasion ≥ mm3 | Adhesion strength between layers of cloth (N/mm) | Adhesion strength between cover layer and cloth layer (/mm) | |

| Covering layer thickness 0.8~1.5mm | Cover layer thickness> 1.5mm | |||||

| A | 17 | 400 | 70 | 6 | 4 | 4.8 |

| E | 14 | 300 | - | |||

| F | 14 | 300 | - | |||

| M | 24 | 450 | 125 | |||

| N | 17 | 400 | 200 | |||

| S | 14 | 300 | 250 | |||

| S* | 12 | 300 | 250 | |||

| South Africa SANS 1173:2005 | ||||||

| Grade | Tensile strength ≥ Ma | Elongation at break ≥ M% | Abrasion ≥ mm3 | Adhesion strength between layers of cloth (N/mm) | ||

| Adhesive strength between cover layer and cloth layer (N/mm) | ||||||

| A | 18 | 400 | 90 | ≥ 7 | ≥ 5 | |

| X | 25 | 450 | 120 | |||

| M | 24 | 450 | 150 | |||

| N | 20 | 400 | 250 | |||

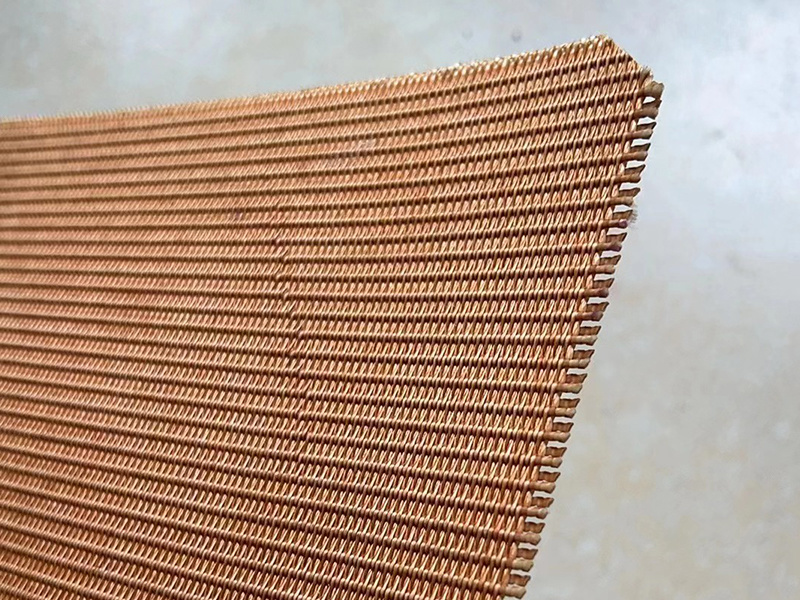

Specification and Technical Parameters of Nylon Multilayer Fabric Core Conveyor Belt

| Fabric Type | Fabric construction | Fabric type | Thickness of adhesive tape (mm/p) | Strength series (N/mm) | Cover glue thickness | Width range (mm) | ||||||

| By | Weft | Layer 2 | Layer 3 | 4 floors | 5 floors | 6 layers | Upper covering layer | Lower cover | ||||

| Nylon | cotton nylon | cotton nylon | Nn-100 | 1.00 | 200 | 300 | 400 | 500 | 600 | 0-12 | 0-10 | 300-2500 |

| Nn-125 | 1.05 | 250 | 375 | 500 | 625 | 750 | ||||||

| Nn-150 | 1.10 | 300 | 450 | 600 | 750 | 900 | ||||||

| Nn-200 | 1.20 | 400 | 600 | 800 | 1000 | 1200 | ||||||

| Nn-250 | 1.40 | 500 | 750 | 1000 | 1250 | 1500 | ||||||

| Nn-300 | 1.60 | 600 | 900 | 1200 | 1500 | 1800 | ||||||

Adhesive strength, elongation performance in accordance with the following table

| Adhesion strength, elongation performance | |||||

| Core material | bond strength | Extension performance | |||

| Interlayer N/mm | Covering layer and layer N/mm | Full thickness longitudinal elongation at break | Full thickness longitudinal reference force elongation | ||

| Covering layer thickness ≤ 1.5mm | Covering layer thickness ≥ 1.5mm | ||||

| Polyester Canvas | ≥ 5 | ≥ 4.5 | ≥ 5 | ≥ 10% | ≤ 4% 6 |

The covering performance of the tape is in accordance with the following table

| Covering performance of tape | |||||

| Overlay Level | Tensile strength | Elongation at break | Abrasion | Change rate of tensile strength and elongation at break after aging | |

| Mpa | Kgf/cm2 | % | mm3 | % | |

| H | ≥ 24 | ≥ 240 | ≥ 450 | ≤ 120 | -25~ 25 |

| D | ≥ 18 | 180 | ≥ 400 | ≤100 | -25~ 25 |

| L | ≥ 15 | 150 | ≥ 350 | ≤200 | -25~ 25 |

FAQ

Characteristics of Polyester Conveyor Belt

High modulus, low elongation, good heat stability, impact resistance and other characteristics, suitable for medium and long distance, high-speed, high-speed conditions of conveying materials.

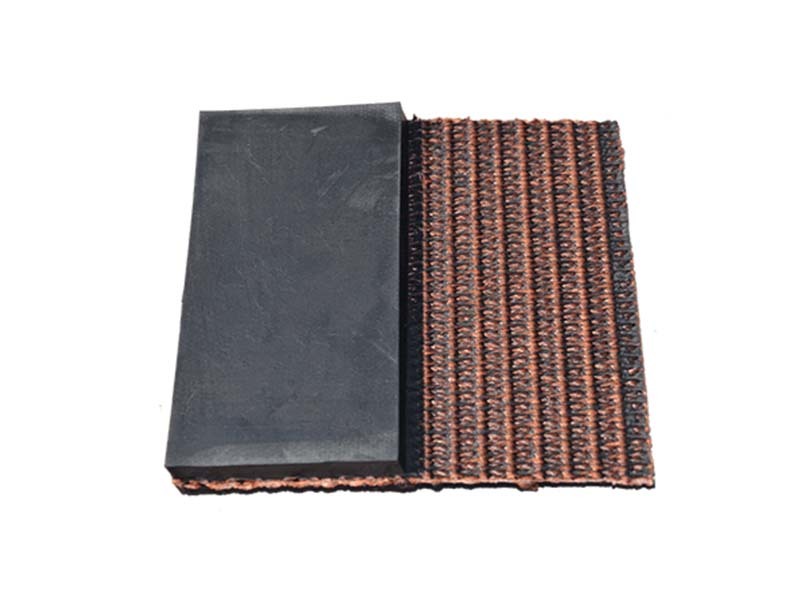

Body material for heat-resistant conveyor belts

The subject material of the heat-resistant conveyor belt includes a skeleton material, a covering layer and a base material.

Selection of the diameter of the conveying roller

The selection of roller diameter should consider the following factors: the average specific pressure between the conveyor belt and the roller surface, the amount of deformation of the bag and the bag, the utilization rate of the allowable strength of the conveyor belt, the frequency of bending of the conveyor belt, the installation location of the conveyor and the conditions of use.

Main material of nylon conveyor belt

The main material of the nylon conveyor belt is nylon, but it does not have enough tension, so it is necessary to add a layer of industrial polyester cloth between nylon and nylon to increase the tension when making the finished product.

The advantages of the pattern conveyor belt

The pattern conveyor belt can ensure the smooth transportation of materials, with anti-skid, impact resistance, and high temperature resistance.

Related Products

Product inquiry

To: Baoding Fangnuo Rubber Products Manufacturing Co., Ltd.