Baoding Fangnuo Rubber Products Manufacturing Co., Ltd.

-

-

Fabric core conveyor belt series

-

High wear-resistant energy-saving conveyor belt

-

(EP) Polyester conveyor belt

-

Nylon conveyor belt

-

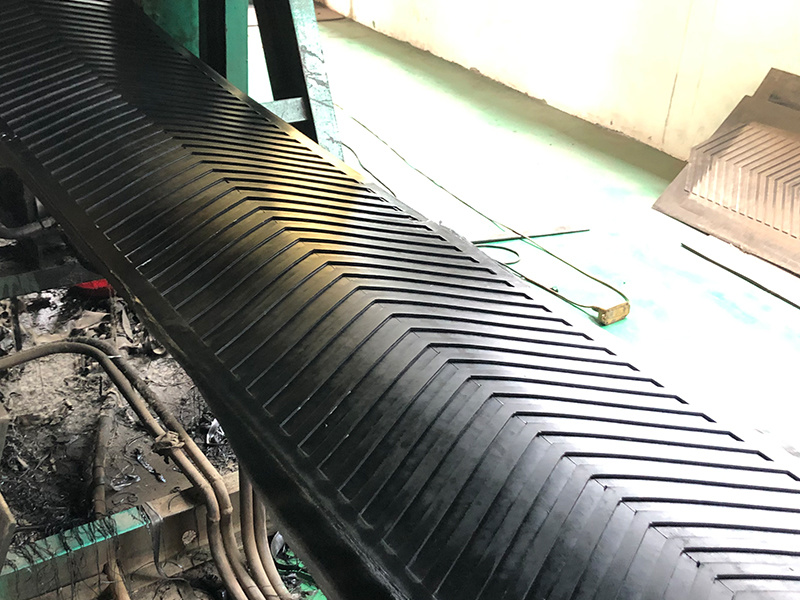

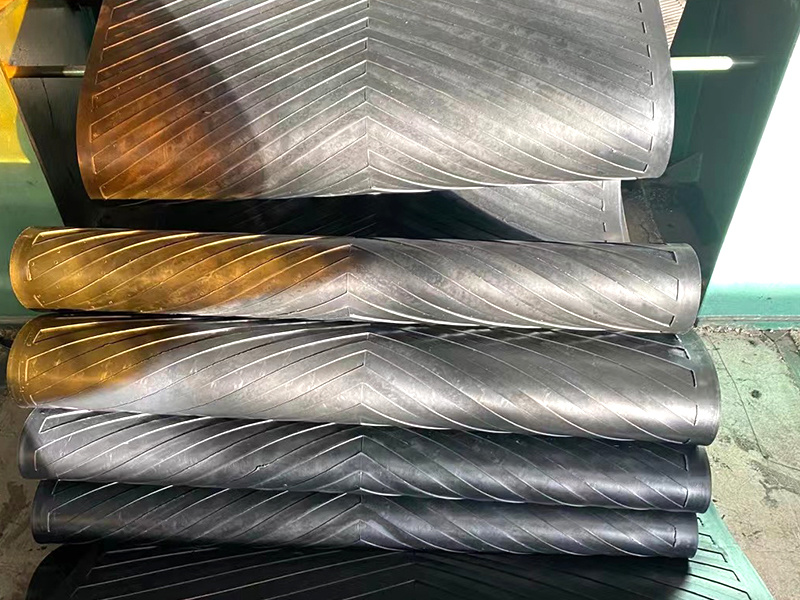

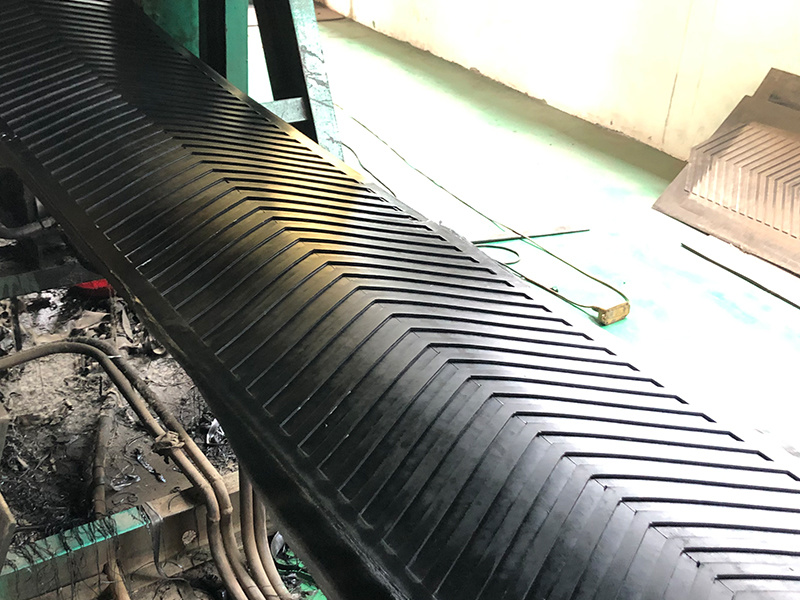

Chevron conveyor belt

-

Ring conveyor belt

-

Super wear-resistant conveyor belt

-

Food and agriculture non-slip conveyor belt

-

Impact-resistant and tear-resistant steel mesh conveyor belt

-

Cut edge conveyor belt

-

Extra-wide conveyor belt

View More -

-

-

Special conveyor belt series

-

Steel cord conveyor belt

-

Vacuum filter conveyor belt

-

High-angle bucket elevator belt

-

Corrugated sidewall conveyor belt

-

Rubber sheet/rubber block/rubber pad

-

Aramid conveyor belt

-

SW conveyor belt (warp)

-

Backless/backless conveyor belt

-

Food-grade white conveyor belt

View More -

-

-

Products

Contact Information

Address: China (Boye) conveyor belt Industrial zone

Whatsapp:+86 18395653111

Mailbox:colin@bestbelting.com

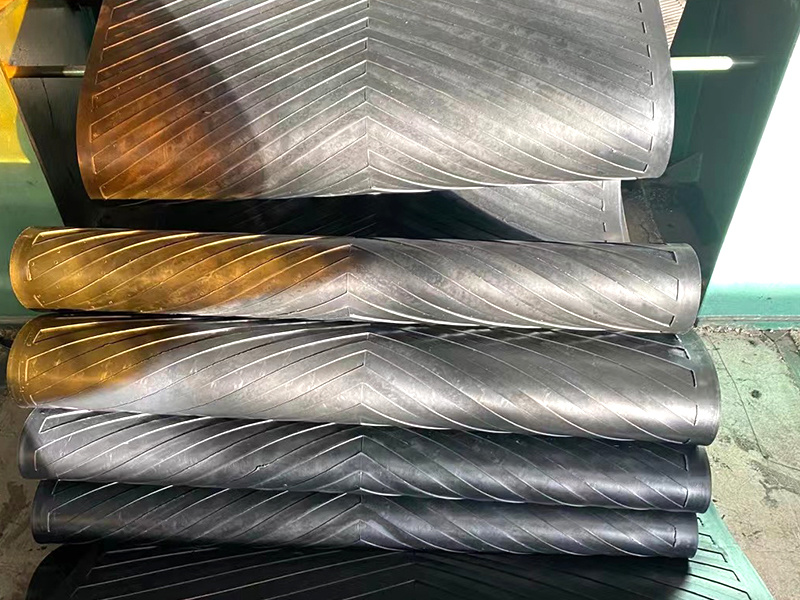

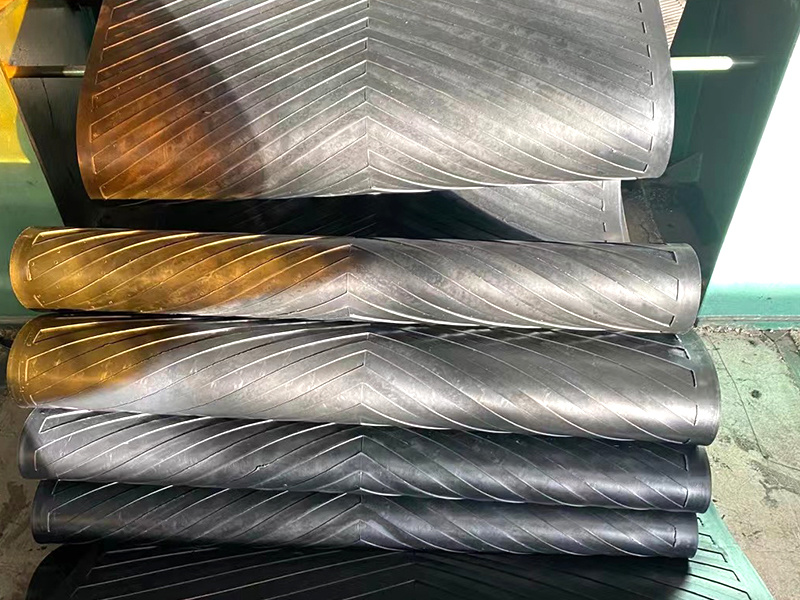

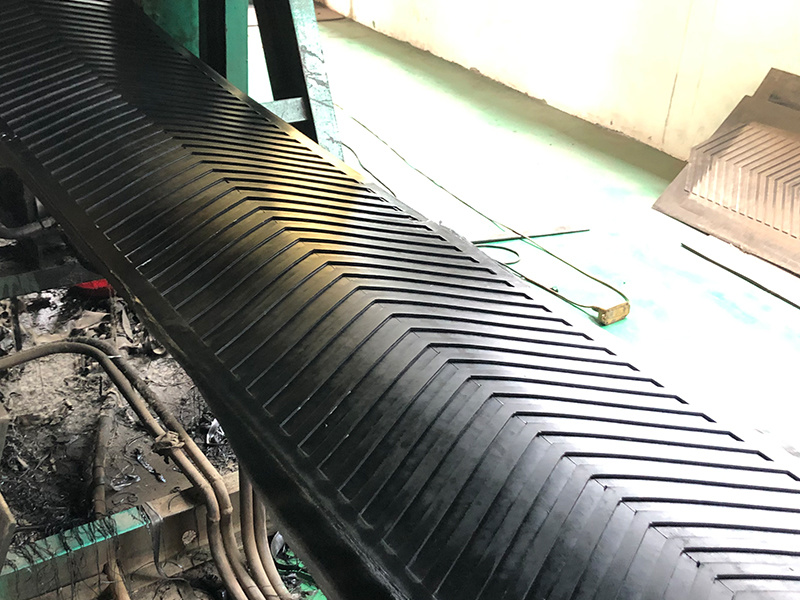

Non-slip recessed herringbone pattern conveyor belt for grain

Keyword:

Non-slip recessed herringbone pattern conveyor belt for grain

Details

Uses

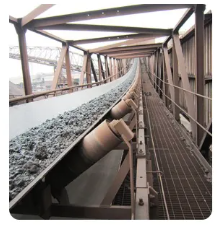

• Grain industry: Suitable for the conveying and loading and unloading of grain, such as in grain depots and flour mills, effectively preventing grain particles from rolling or slipping on the conveyor belt, reducing material loss.

• Mining industry: Used to convey bulk materials such as coal and ore. Its anti-slip performance prevents materials from slipping during inclined conveying, ensuring stable and efficient conveying.

• Construction industry: Can be used to convey construction materials such as sand, gravel, and cement. It can adapt to different conveying angles and ensure that materials are accurately conveyed to the designated location.

• Chemical industry: For some powdery or small granular chemical raw materials, the recessed chevron conveyor belt can provide good anti-slip performance during conveying, preventing materials from scattering due to the inclination of the conveyor belt, ensuring production safety and environmental hygiene.

Features

In addition to good anti-slip performance, the recessed chevron conveyor belt also has the following features:

• Excellent drainage: The recessed chevron pattern design is conducive to drainage. When conveying wet materials or working in a humid environment, it can quickly drain water, preventing materials from slipping due to water accumulation or damage to the conveyor belt surface.

• High conveying efficiency: The unique pattern increases the friction between the material and the conveyor belt, keeping the material stable during conveying and preventing slippage or rolling, thereby improving conveying efficiency and reducing material loss during conveying.

• Strong applicability: Different core materials and cover rubber materials can be selected according to different conveying needs to adapt to various working environments, such as special requirements for oil resistance, heat resistance, and cold resistance.

• Long service life: This conveyor belt has a reasonable structural design, high belt strength, and maintains a certain conveying performance even after the pattern is worn. Maintenance is relatively simple, so it has a long service life.

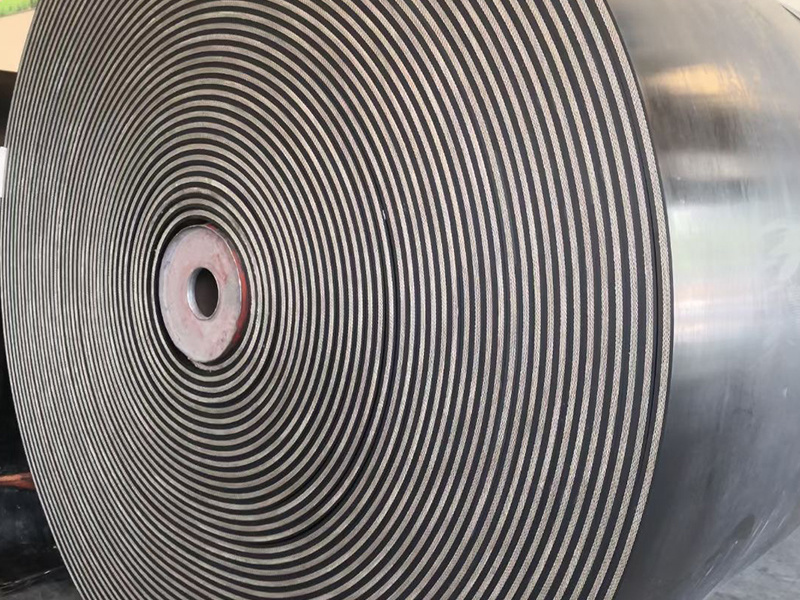

Product photos

|

|

|

Cover rubber quality/grade standard performance parameters

| German standard DIN-22102 | ||||||

| Grade | Tensile strength ≥Ma | Elongation at break ≥M% | Abrasion ≥mm 3 | Inter-ply adhesion strength (N/mm) | Adhesion strength between cover and carcass (/mm) | |

| Cover thickness 0.8~1.5mm | Cover thickness >1.5mm | |||||

| W | 18 | 400 | 90 | ≥5 | 3.5 | 4.5 |

| X | 25 | 450 | 120 | |||

| Y | 20 | 400 | 150 | |||

| Z | 15 | 350 | 250 | |||

| British Standard BS 490 | ||||||

| Grade | Tensile strength ≥Ma | Elongation at break ≥M% | Abrasion ≥mm 3 | Inter-ply adhesion strength (N/mm) | Adhesion strength between cover and carcass (/mm) | |

| Cover thickness 0.8~1.5mm | Cover thickness >1.5mm | |||||

| M | 24 | 450 | - | ≥5.25 | 3.15 | 4.5 |

| N | 17 | 400 | - | |||

| Australian Standard AS 1332-2000 | ||||||

| Grade | Tensile strength ≥Ma | Elongation at break ≥M% | Abrasion ≥mm 3 | Inter-ply adhesion strength (N/mm) | Adhesion strength between cover and carcass (/mm) | |

| Cover thickness 0.8~1.5mm | Cover thickness >1.5mm | |||||

| A | 17 | 400 | 70 | 6 | 4 | 4.8 |

| E | 14 | 300 | - | |||

| F | 14 | 300 | - | |||

| M | 24 | 450 | 125 | |||

| N | 17 | 400 | 200 | |||

| S | 14 | 300 | 250 | |||

| S* | 12 | 300 | 250 | |||

| South African SANS 1173:2005 | ||||||

| Grade | Tensile strength ≥Ma | Elongation at break ≥M% | Abrasion ≥mm 3 | Inter-ply adhesion strength (N/mm) | ||

| Adhesion strength between cover and carcass (N/mm) | ||||||

| A | 18 | 400 | 90 | ≥7 | ≥5 | |

| X | 25 | 450 | 120 | |||

| M | 24 | 450 | 150 | |||

| N | 20 | 400 | 250 | |||

Specifications and technical parameters of anti-slip recessed chevron conveyor belts

| Fabric type | Fabric structure | Fabric model | Canvas thickness (mm/p) | Strength series (N/mm) | Cover rubber thickness | Width range (mm) | ||||||

| Warp | Weft | 2 layers | 3 layers | 4 layers | 5 layers | 6 layers | Top cover | Bottom cover | ||||

|

Nylon EP polyester NN EE |

Nylon | Nylon | NN-100 | 1.00 | 200 | 300 | 400 | 500 | 600 | 0-12 | 0-10 | 300-2500 |

| NN-125 | 1.05 | 250 | 375 | 500 | 625 | 750 | ||||||

| NN-150 | 1.10 | 300 | 450 | 600 | 750 | 900 | ||||||

| NN-200 | 1.20 | 400 | 600 | 800 | 1000 | 1200 | ||||||

| NN-250 | 1.40 | 500 | 750 | 1000 | 1250 | 1500 | ||||||

| NN-300 | 1.60 | 600 | 900 | 1200 | 1500 | 1800 | ||||||

Adhesion strength and elongation performance meet the following table

| Adhesion strength, elongation performance | |||||

| Carcass material | Adhesion strength | Elongation performance | |||

| Inter-ply N/mm | Adhesion strength between cover and carcass N/mm | Total thickness longitudinal elongation at break | Total thickness longitudinal reference force elongation | ||

| Cover thickness ≤1.5mm | Cover thickness ≥1.5mm | ||||

|

Nylon EP polyester NN EE |

≥5 | ≥4.5 | ≥5 | ≥10% | ≤4%6 |

The cover performance of the tape meets the following table

| China GB/T7984-2013 GB/T 32457-2015 Tape cover layer performance | |||||

| Cover Layer Level | Tensile Strength | Elongation at Break | Abrasion Loss | Change Rate of Tensile Strength and Elongation at Break After Aging | |

| Mpa | Kgf/cm2 | % | mm 3 | % | |

| H | ≥24 | ≥240 | ≥450 | ≤120 | -25~ +25 |

| D | ≥18 | 180 | ≥400 | ≤100 | -25~ +25 |

| L | ≥15 | 150 | ≥350 | ≤200 | -25~ +25 |

Packaging and Transportation

|

|

|

|

Packaging Details

1. Waterproof nylon packaging, with a bottom steel pallet or wooden pallet.

2. Standard and appropriate export packaging.

3. Customized packaging is available according to customer requirements.

Frequently Asked Questions

1. Can I customize conveyor belts to meet my business needs?

►Yes, we are special ized custom conveyor belt manufacturer , Focusing on customized conveyor belt solutions. We work closely with our clients to customize the belt width, thickness, material composition, and various quality aspects according to their specific operational requirements. This ensures that our conveyor belts perform optimally in diverse industrial settings.

2. What payment methods do you accept?

►We offer flexible payment methods to meet customer needs. Commonly used payment methods include Telegraphic Transfer (T/T) and Letter of Credit (L/C) ,especially suitable for large orders. We can also negotiate other payment methods based on mutual agreement.

3. What after-sales service do you provide? And how do you guarantee your quality?

►We provide comprehensive after-sales service support, including 24/7 technical support, installation assistance, and maintenance advice 。We also provide regular follow-up services to ensure smooth product operation and long-term customer satisfaction! We have an in-house testing laboratory and adhere to the principle of qualified products before shipment! For many years, we have been one of the suppliers to internationally renowned companies, and our customers are located in various countries and industries, including mining, stone crushing, sand washing, ports, power plants, metallurgy, chemicals, coal, steel plants, cement plants, and construction, with our excellent quality widely praised.

4. How do I place an order? What is the delivery time?

►You can contact us via WeChat, WhatsApp, phone, email, and website to place an order. For regular models, 5-7 days delivery ,the delivery time for other customized products depends on the product type and customization requirements.

5. Can I get samples for inspection and testing?

►Yes, samples can be sent for testing before bulk orders. Samples are created according to customer requirements, allowing customers to evaluate the performance of the belts and rollers.

6. Can I print my LOGO on the conveyor belt products?

►Yes, we are a custom manufacturer, supporting processing, OEM, please inform us of your logo or design before mass production.

| Strong Team with Rich Experience | Advanced and First-Class Production Equipment | First-Class Testing Equipment | Successful Customer Collaboration |

|

|

|

|

| Our global sales and R&D teams go beyond transactional relationships, providing personalized support at every stage of the customer journey. | We have invested heavily in advanced conveyor belt production lines, including automated systems that guarantee the precision, reliability, and scalability of our products. | We have in-house testing equipment to ensure that every conveyor belt we produce undergoes rigorous quality control. From tensile strength and abrasion resistance to high-temperature resistance, we can meet your requirements. | We have established long-term partnerships with customers in the cement, mining, power plants, chemical, steel, coal, mining, and grain industries, fully demonstrating the trust and confidence that enterprises have in us. |

Why Choose Our Conveyor Belts?

1. Engineering Design and Consulting

FANGNUO Rubber Conveyor Belt is one of the best custom belt manufacturers in China. Our conveyor belts are ideal for handling bulk materials, various heavy-duty and abrasive materials, successfully meeting the needs of various industries, including stone crushing and screening, sand washing, chemical fertilizers, grain conveying, steel plants, power plants, cement plants, metallurgy, coal, ports, construction, etc. As a one-stop conveyor engineering manufacturer, we also provide excellent solutions for material handling problems and after-sales service for various applications.

2. Excellent Customer Service

We specialize in producing heavy-duty (nylon, EP polyester, EE, NN) multi-ply fabric core rubber conveyor belts, steel cord conveyor belts, corrugated edge conveyor belts, bucket elevator conveyor belts, herringbone conveyor belts, and circular conveyor belts. As a high-quality conveyor belt manufacturer, supplier, and exporter in China, we are committed to providing customers with high-quality conveyor belts and professional services. FANGNUO has grown rapidly through innovation and professional services, and we are eager to expand our domestic and international markets!

3. Customization

OEM is supported to meet all your needs, regardless of size, even if you only have an idea, we will help you realize it.

We have a strong R&D team that can develop and produce products based on drawings or samples provided by customers.

4. Cost-Effective

Same quality, lower price; same price, better quality; fast production cycle; short time; efficient and durable; reliable quality. We are based in the mid-to-high-end market, and our products meet international standards.

Professional testing equipment (conveyor belt testing laboratory)

Application Areas

Cement Industry Limestone Transportation |

Chemical Industry Hazardous Materials Transportation |

Mining Industry Raw Material Transportation |

Quarrying Sand and Gravel Conveying |

FAQ

Characteristics of Polyester Conveyor Belt

High modulus, low elongation, good heat stability, impact resistance and other characteristics, suitable for medium and long distance, high-speed, high-speed conditions of conveying materials.

Body material for heat-resistant conveyor belts

The subject material of the heat-resistant conveyor belt includes a skeleton material, a covering layer and a base material.

Selection of the diameter of the conveying roller

The selection of roller diameter should consider the following factors: the average specific pressure between the conveyor belt and the roller surface, the amount of deformation of the bag and the bag, the utilization rate of the allowable strength of the conveyor belt, the frequency of bending of the conveyor belt, the installation location of the conveyor and the conditions of use.

Main material of nylon conveyor belt

The main material of the nylon conveyor belt is nylon, but it does not have enough tension, so it is necessary to add a layer of industrial polyester cloth between nylon and nylon to increase the tension when making the finished product.

The advantages of the pattern conveyor belt

The pattern conveyor belt can ensure the smooth transportation of materials, with anti-skid, impact resistance, and high temperature resistance.

Related Products

Product inquiry

To: Baoding Fangnuo Rubber Products Manufacturing Co., Ltd.

Product

About Us

We specialize in producing heavy-duty EP nylon conveyor belts, steel cord conveyor belts, corrugated rib conveyor belts, bucket elevator conveyor belts, herringbone conveyor belts, ring conveyor belts, etc. As a Chinese conveyor belt manufacturer, supplier and exporter, we focus on providing customers with high-quality conveyor belts and better services.

Baoding Fangnuo Rubber Products Manufacturing Co., Ltd.

Copyright Baoding Fangnuo Rubber Products Manufacturing Co., Ltd., All rights reserved