Baoding Fangnuo Rubber Products Manufacturing Co., Ltd.

-

-

Fabric core conveyor belt series

-

High wear-resistant energy-saving conveyor belt

-

(EP) Polyester conveyor belt

-

Nylon conveyor belt

-

Chevron conveyor belt

-

Ring conveyor belt

-

Super wear-resistant conveyor belt

-

Food and agriculture non-slip conveyor belt

-

Impact-resistant and tear-resistant steel mesh conveyor belt

-

Cut edge conveyor belt

-

Extra-wide conveyor belt

View More -

-

-

Special conveyor belt series

-

Steel cord conveyor belt

-

Vacuum filter conveyor belt

-

High-angle bucket elevator belt

-

Corrugated sidewall conveyor belt

-

Rubber sheet/rubber block/rubber pad

-

Aramid conveyor belt

-

SW conveyor belt (warp)

-

Backless/backless conveyor belt

-

Food-grade white conveyor belt

View More -

-

-

Products

Contact Information

Address: China (Boye) conveyor belt Industrial zone

Whatsapp:+86 18395653111

Mailbox:colin@bestbelting.com

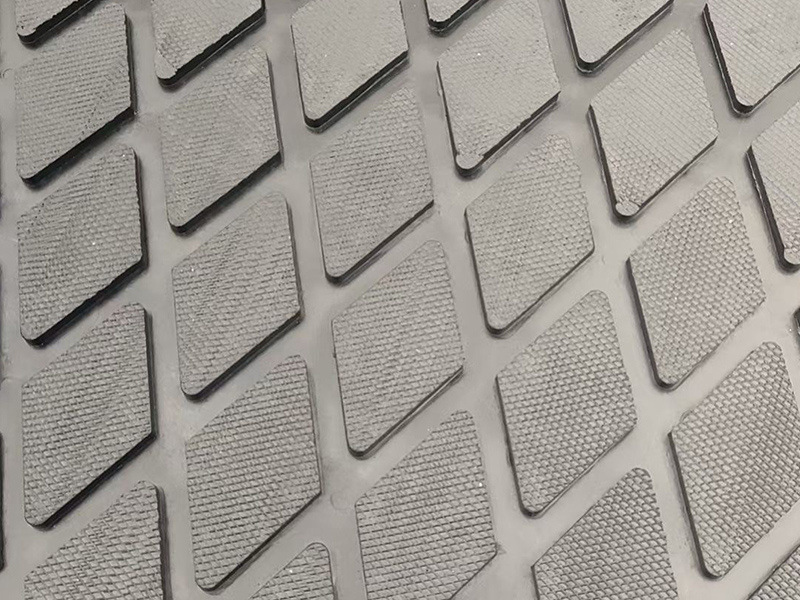

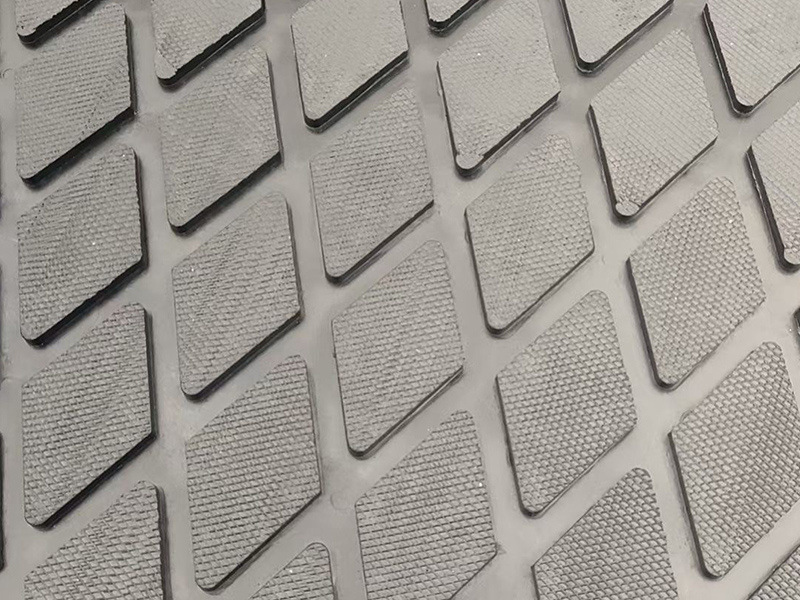

Rhombus glue plate

Keyword:

Rhombus glue plate

Product Description

Diamond-pattern rubber sheeting is a widely used wear-resistant rubber material in roller cladding construction. Its surface features a diamond pattern, pressed onto the rubber base material through a special process to enhance friction and anti-slip properties.

Characteristics

• Pattern Design: Primarily featuring large diamond patterns of 85*50mm, effectively dispersing impact force generated on the roller surface by materials, reducing roller wear.

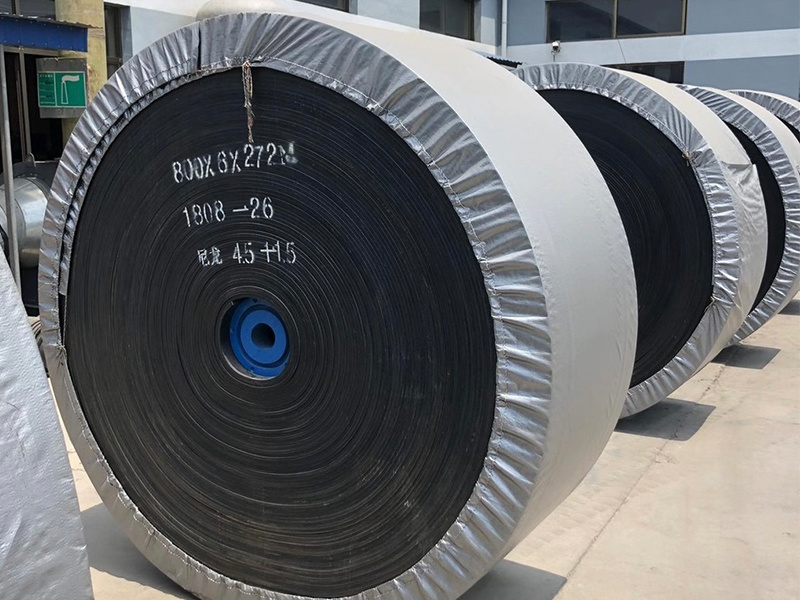

• Thickness and Width: Common thicknesses include 8mm, 10mm, 12mm, 15mm, and 20mm, with a standard width of 2000mm, suitable for rollers of various sizes.

• Physical and Chemical Properties: Made from high-quality wear-resistant rubber, it possesses high elasticity, high wear resistance, moderate hardness, acid and alkali corrosion resistance, cold and heat resistance, effectively extending equipment lifespan.

Applications

• Roller Cladding: Primarily used for cladding drive rollers or idler rollers, commonly applied in conveyor belt maintenance.

• Material Conveying: Increases friction between materials and rollers, improving conveying efficiency, reducing roller wear, and widely used in coal, mining, port, metallurgical, and chemical industries.

• Environmental Adaptability: Operates normally in harsh environments such as wet mud, protecting rollers from material adhesion and preventing deviation.

Technical Features

• One-Piece Molding: One-piece molding during production, with clear surface patterns, uniform thickness, eliminating the time required for carving patterns during roller cladding.

• High Tensile Strength: Meets the high-strength wear resistance requirements of roller cladding.

• Simplified Construction: Can be used with metal treatment agents and cold vulcanization two-component cold vulcanizing agents to improve the bonding force between the roller and the rubber sheeting, simplifying the surface treatment process of the sheeting.

• Custom Processing: Can be custom-processed according to different roller sizes and technical requirements, with prefabricated joints for convenient on-site construction.

Installation and Construction

• Pre-construction Preparation: Use an angle grinder with a tungsten steel grinding disc to remove rust, oil stains, and old glue layers from the roller surface until a metallic luster is achieved; accurately measure and cut the diamond rubber sheeting according to the roller circumference and width, leaving a 30-50mm overlap.

• Glue Application and Treatment: Apply cleaning agent and metal treatment agent to the polished roller. After drying, use the matching roller cladding adhesive, and evenly apply the adhesive to the bonding surface of the roller and the diamond rubber sheeting, following the principle of thin and even application. After the first layer of adhesive dries to the point where it is not sticky to the touch but still has some tackiness, apply a second layer of adhesive.

• Sheeting Bonding and Roller Installation: Starting from one end of the roller, slowly and evenly bond the cut diamond sheeting to the roller surface, simultaneously using a pressure roller or rubber hammer to gradually press from the center of the sheeting to both sides; after cladding is complete, let the roller sit until the adhesive is fully cured (generally about 24 hours at room temperature), then install it onto the conveying equipment.

FAQ

Characteristics of Polyester Conveyor Belt

High modulus, low elongation, good heat stability, impact resistance and other characteristics, suitable for medium and long distance, high-speed, high-speed conditions of conveying materials.

Body material for heat-resistant conveyor belts

The subject material of the heat-resistant conveyor belt includes a skeleton material, a covering layer and a base material.

Selection of the diameter of the conveying roller

The selection of roller diameter should consider the following factors: the average specific pressure between the conveyor belt and the roller surface, the amount of deformation of the bag and the bag, the utilization rate of the allowable strength of the conveyor belt, the frequency of bending of the conveyor belt, the installation location of the conveyor and the conditions of use.

Main material of nylon conveyor belt

The main material of the nylon conveyor belt is nylon, but it does not have enough tension, so it is necessary to add a layer of industrial polyester cloth between nylon and nylon to increase the tension when making the finished product.

The advantages of the pattern conveyor belt

The pattern conveyor belt can ensure the smooth transportation of materials, with anti-skid, impact resistance, and high temperature resistance.

Related Products

Product inquiry

To: Baoding Fangnuo Rubber Products Manufacturing Co., Ltd.

Product

About Us

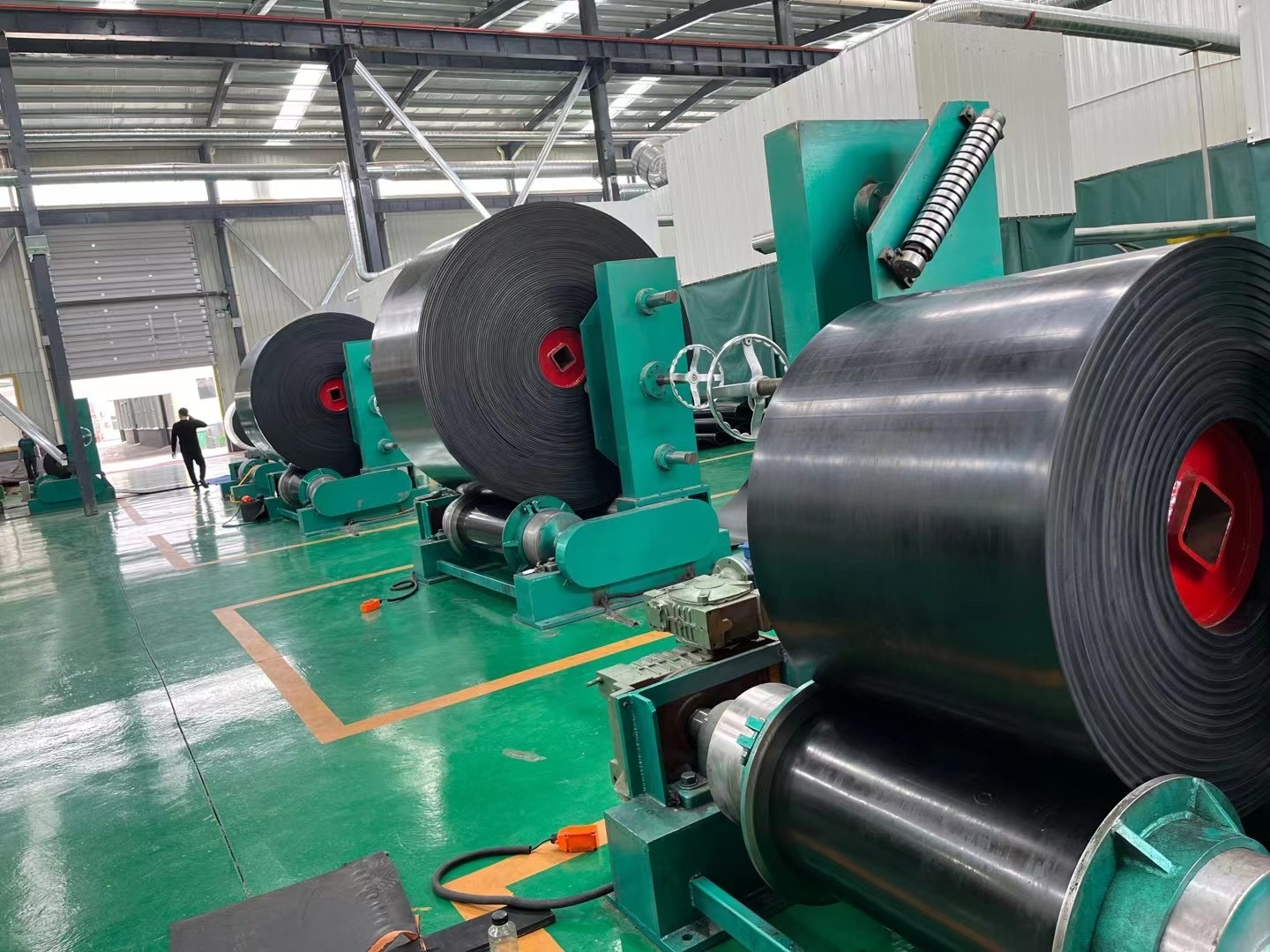

We specialize in producing heavy-duty EP nylon conveyor belts, steel cord conveyor belts, corrugated rib conveyor belts, bucket elevator conveyor belts, herringbone conveyor belts, ring conveyor belts, etc. As a Chinese conveyor belt manufacturer, supplier and exporter, we focus on providing customers with high-quality conveyor belts and better services.

Baoding Fangnuo Rubber Products Manufacturing Co., Ltd.

Copyright Baoding Fangnuo Rubber Products Manufacturing Co., Ltd., All rights reserved