Baoding Fangnuo Rubber Products Manufacturing Co., Ltd.

-

-

Fabric core conveyor belt series

-

High wear-resistant energy-saving conveyor belt

-

(EP) Polyester conveyor belt

-

Nylon conveyor belt

-

Chevron conveyor belt

-

Ring conveyor belt

-

Super wear-resistant conveyor belt

-

Food and agriculture non-slip conveyor belt

-

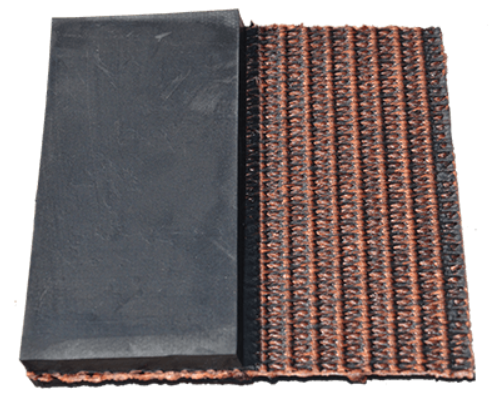

Impact-resistant and tear-resistant steel mesh conveyor belt

-

Cut edge conveyor belt

-

Extra-wide conveyor belt

View More -

-

-

Special conveyor belt series

-

Steel cord conveyor belt

-

Vacuum filter conveyor belt

-

High-angle bucket elevator belt

-

Corrugated sidewall conveyor belt

-

Rubber sheet/rubber block/rubber pad

-

Aramid conveyor belt

-

SW conveyor belt (warp)

-

Backless/backless conveyor belt

-

Food-grade white conveyor belt

View More -

-

-

Product recommendation

We offer a full range of conveyor belts, conveyor rollers/mobile conveyor industrial equipment. Our conveyor belts are very suitable for bulk handling of various heavy and abrasive materials, successfully meeting the needs of various industries, grain, stone crushing and screening, sand washing, fertilizer, steel mills, etc.

Super wear-resistant conveyor belt

High wear-resistant energy-saving rubber conveyor belt

Oil-resistant NBR/MOR conveyor belt

Backless/backless conveyor belt

SBR heat and high temperature resistant conveyor belt

Multi-layer fabric core conveyor belt series

Nylon conveyor belt | EP polyester conveyor belt | ultra-wear-resistant conveyor belt | high wear-resistant conveyor belt | tear-resistant and impact-resistant steel cord conveyor belt | herringbone conveyor belt | ring conveyor belt | grain and agriculture anti-skid concave special conveyor belt | edge-cut conveyor belt | extra-wide conveyor belt

Special attribute conveyor belt series

Oil-resistant conveyor belt | Cold-resistant conveyor belt | Heat-resistant and high-temperature conveyor belt | Fire-resistant, flame-retardant, and scorch-resistant conveyor belt | Acid-resistant, alkali-resistant, and chemically corrosion-resistant conveyor belt

Backless conveyor belt | Corrugated edge conveyor belt | Steep angle bucket elevator belt | Vacuum filter conveyor belt | Food grade white conveyor belt | Straight warp SW conveyor belt | Aramid conveyor belt | Steel wire core conveyor belt | Rubber pad / rubber sheet / rubber block

Conveyor accessories idler/roller/series

Conveying accessories Conveying rollers (Rollers Head Pulley) (Rollers Tail pulley) | Idler rollers (Roller)

Who Are We?

Fangnuo Rubber-Quality Conveyor Belt Supplier

Why choose us?

Engineering Design and Consulting

Fono Rubber Conveyor Belt is a custom belt manufacturer. Our conveyor belts are very suitable for bulk handling of various heavy and abrasive materials, successfully meeting the needs of various industries, stone crushing and screening, sand washing, fertilizers, grain conveying, steel mills, etc. As a one-stop engineering solution, we also provide excellent after-sales service for various applications, including belt joint materials, heat vulcanizing machines, belt repair materials, belt clamping, belt splicing services, etc.

Excellent customer service

We specialize in producing heavy-duty EP nylon conveyor belts, steel cord conveyor belts, corrugated rib conveyor belts, bucket elevator conveyor belts, herringbone conveyor belts, ring conveyor belts, etc. As a Chinese high-quality conveyor belt manufacturer, supplier and exporter, we focus on providing customers with high-quality conveyor belts and professional services. Due to the rapid growth of Fono with innovation and professional services, we are eager to expand our domestic and international markets

Customization

Meet all your needs, no matter the size, even if you only have ideas, we will help you to achieve.

We have a strong R&D technology team that can develop and produce products based on the drawings or samples provided by customers.

Cost performance

Same quality, lowest price, same price, best quality, fast production cycle, short time, high efficiency, durability, reliable quality

Be Founded In

Existing customers

Sales country and region

Based on China, serving the world

The company was established in2018Year, product sales all over the world and domestic40Multiple areas!

Our customers are located in Russia, Indonesia, Zambia, Turkey, the Philippines, Myanmar, Thailand, the United Arab Emirates, India, Pakistan, the United States and China, etc., and we have high-quality partnerships with domestic state-owned enterprises in China, such as: China Railway First Bureau, China Petrochemical Corporation, China Baowu Iron and Steel Group Co., Ltd., China Shipbuilding Industry Group Co., Ltd., Shougang Group Co., Ltd, shandong Iron and Steel Group Co., Ltd.

Featured Products

Complete conveyor belt product solution supplier

The recessed inverted-V conveyor belt features an inverted-V structure with a recessed center and slightly raised sides. Its strong drainage and diversion capabilities make it ideal for use at the junctions of roofs and walls or in floor expansion joints. It effectively diverts accumulated water, preventing leakage. It is characterized by its robust structure, excellent waterproof performance, and ease of installation.

The sidewall conveyor belt must be able to withstand very high stresses and repeated bending that occur during high-capacity, steep-angle conveying. Due to site limitations or the need to elevate materials at a large inclination angle, this is to prevent the conveyed materials from scattering.

Steel cord conveyor belts have proven to be a very reliable and cost-effective method for conveying bulk materials in long-distance conveyors. We offer laterally reinforced belts, belts with embedded sensor coils, and standard steel cord conveyor belts. (1) Belt elongation: ST500~ST5000(kN/m) (2) Belt width: 600~2200mm (3) Minimum length: 100m

Cold-resistant conveyor belts are characterized by high elasticity, impact resistance, and cold resistance, and can be used normally at -40°C without breaking. They are widely used in cement, coking, metallurgy, chemical, and steel industries in areas with temperatures as low as -40°C for conveying shorter distances and smaller quantities.

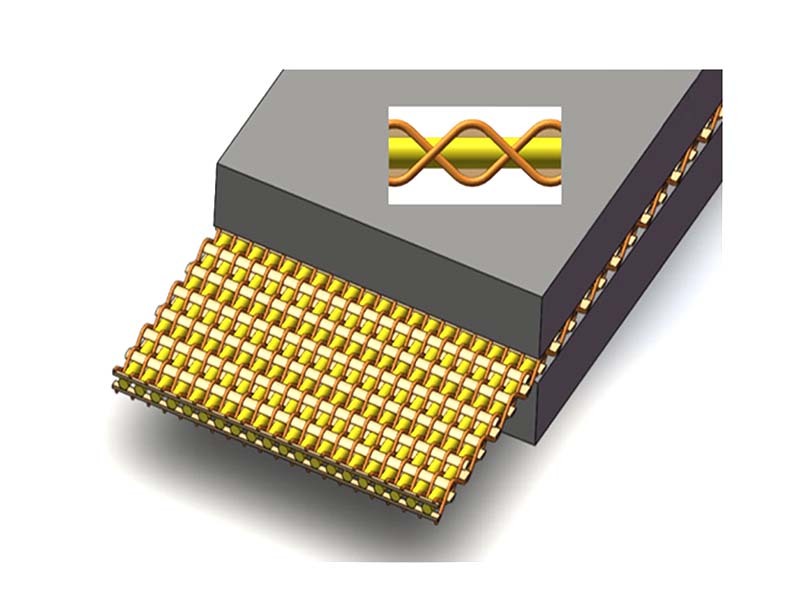

SW conveyor belts are high-performance conveying equipment: Wide application: Suitable for scenarios with large drops, high loads, and high-speed conveying, commonly used in mining, ports, and other industries. Superior structure: Thin belt core, replacing multi-layer with single/double layer, thickness reduced by 7% - 17%, single roll length up to 400 - 500 meters, adaptable to small rollers. Strong performance: Using special weaving methods, high tensile strength, low elongation; special organizational structure, strong impact absorption, good toughness, and long service life. Suitable for conveying materials with large drops, high loads, and high-speed conditions, widely used in mining, ports, power, and other industries.

Aramid conveyor belts combine high-strength, lightweight materials with multi-functional covering materials, making the product perfectly suitable for a wide range of applications. Aramid fiber reinforced rubber conveyor belts are high-performance conveyor products made by combining aramid fibers as the core reinforcing material with rubber through a special process.

Enterprise advantage

We offer a full range of conveyor belts, conveyor rollers/mobile conveyor industrial equipment. Our conveyor belts are very suitable for bulk handling of various heavy and abrasive materials, successfully meeting the needs of various industries, grain, stone crushing and screening, sand washing, fertilizer, steel mills, etc.

Service Industry

Metro tunnels, cement plants, power plants, grain transportation, machinery manufacturing plants, quarries, metallurgy, waste recycling plants, chemicals, thermal power plants, mines, ports, coal preparation plants, ports and railways, chemicals and processing, mining and minerals, Energy and power oil & gas, ports and coal mining engineering fields. It can also provide a wide range of other products and services related to ceramic pulley encapsulation, rubber non-slip mats around stables, sidewalks and paddock, and belt fasteners.

Specialized equipment

Fono Rubber is committed to achieving high quality standards for all products and services in terms of regulatory requirements and customer quality expectations. Experienced engineers and selection software can help customers design all conveyor systems. Domestic wide vulcanizing machine, can meet the width of 6 meters conveyor belt production. With excellent formula and production process, known in the country!

Quality Assurance

As all product quality meets industry standards, we believe to be your preferred conveyor belt supplier. The employees of Fono are fully committed to providing their expertise in product and service excellence. With its professionalism and our extensive experience in this market, we have gained confidence and good feedback.

High quality supplier

Our customers are located in Russia, Indonesia, Zambia, Turkey, the Philippines, Myanmar, Thailand, the United Arab Emirates, India, Pakistan, the United States and China, etc., and we have high-quality partnerships with domestic state-owned enterprises in China, such as: China Railway First Bureau, China Petrochemical Corporation, China Baowu Iron and Steel Group Co., Ltd., China Shipbuilding Industry Group Co., Ltd., Shougang Group Co., Ltd., Shandong Iron and Steel Group Co., etc.

News

Complete conveyor belt product solution supplier

Product

About Us

We specialize in producing heavy-duty EP nylon conveyor belts, steel cord conveyor belts, corrugated rib conveyor belts, bucket elevator conveyor belts, herringbone conveyor belts, ring conveyor belts, etc. As a Chinese conveyor belt manufacturer, supplier and exporter, we focus on providing customers with high-quality conveyor belts and better services.

Baoding Fangnuo Rubber Products Manufacturing Co., Ltd.

Copyright Baoding Fangnuo Rubber Products Manufacturing Co., Ltd., All rights reserved