Baoding Fangnuo Rubber Products Manufacturing Co., Ltd.

-

-

Fabric core conveyor belt series

-

High wear-resistant energy-saving conveyor belt

-

(EP) Polyester conveyor belt

-

Nylon conveyor belt

-

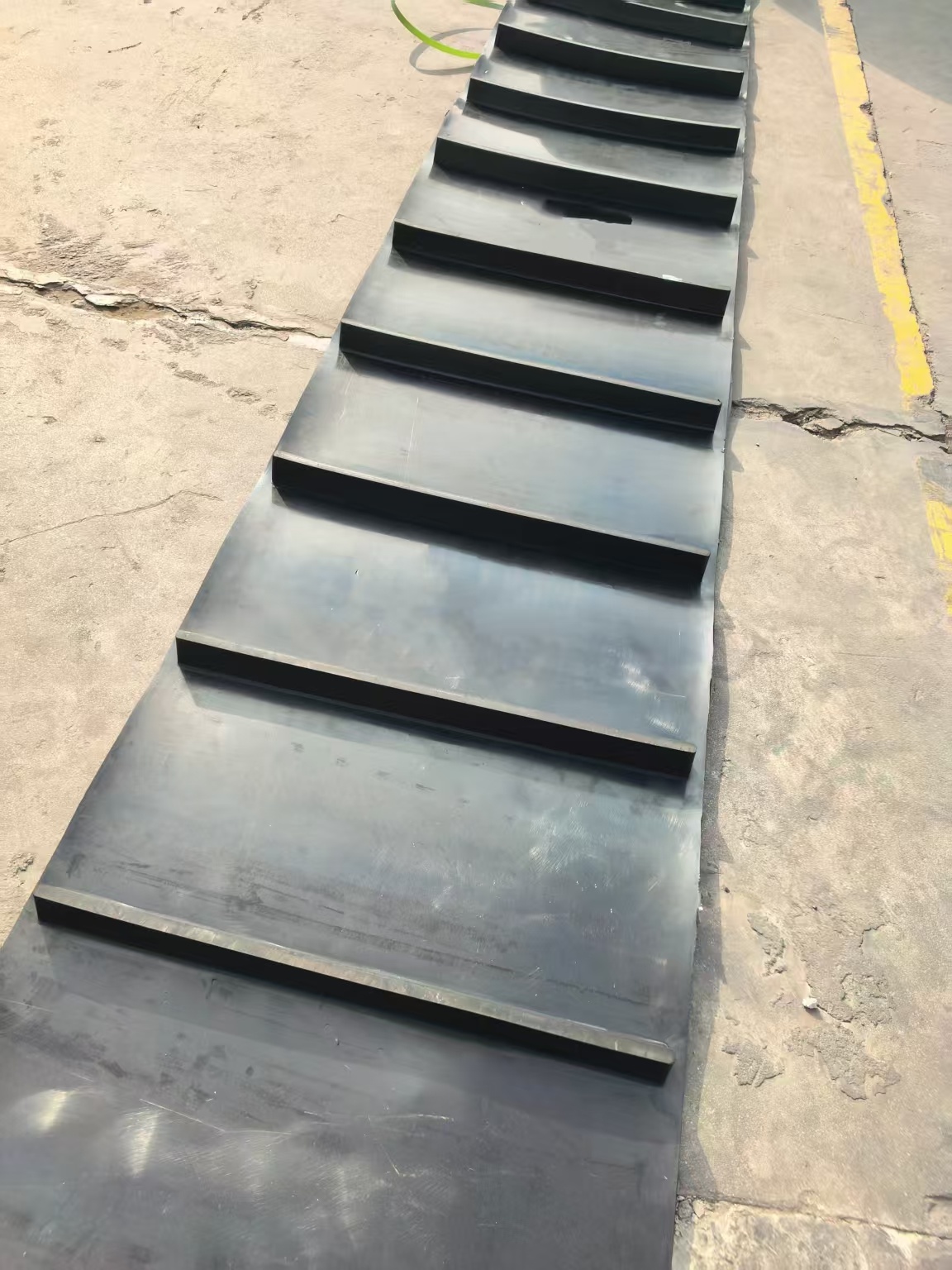

Chevron conveyor belt

-

Ring conveyor belt

-

Super wear-resistant conveyor belt

-

Food and agriculture non-slip conveyor belt

-

Impact-resistant and tear-resistant steel mesh conveyor belt

-

Cut edge conveyor belt

-

Extra-wide conveyor belt

View More -

-

-

Special conveyor belt series

-

Steel cord conveyor belt

-

Vacuum filter conveyor belt

-

High-angle bucket elevator belt

-

Corrugated sidewall conveyor belt

-

Rubber sheet/rubber block/rubber pad

-

Aramid conveyor belt

-

SW conveyor belt (warp)

-

Backless/backless conveyor belt

-

Food-grade white conveyor belt

View More -

-

-

Installation and maintenance tips for herringbone conveyor belt

Release time:

2025-06-10 09:33

The herringbone conveyor belt plays an important role in many industrial fields. Correct installation and maintenance are the key to ensure its efficient operation.

1. Installation tips

Preparation

Before installation, clean the installation site to ensure that there are no debris and obstacles. At the same time, check whether the specifications of the conveyor belt match the equipment, and check whether the surface of the conveyor belt is damaged or deformed.

Adjustment of rollers and rollers

During installation, first ensure that the installation position of the rollers and rollers is accurate. The rollers should be kept horizontal and the axes should be parallel, and the spacing between rollers should be uniform. For herringbone conveyor belts, the angle of the rollers needs to be adjusted appropriately according to the herringbone design of the conveyor belt to ensure that the conveyor belt is evenly stressed during operation and avoid deviation.

Conveyor belt joints

It is crucial to correctly connect the conveyor belt joints. If it is a vulcanized joint, it must be operated in strict accordance with the vulcanization process requirements to control the vulcanization temperature, pressure and time. If it is a mechanical joint, ensure that the joint is firmly connected and the bolts are tightened to the same degree to avoid loosening.

2. Maintenance skills

Daily inspection

Inspect the conveyor belt daily to check whether there are foreign objects attached to the surface of the conveyor belt, such as material residues, oil stains, etc., and clean them in time. At the same time, check the wear of the conveyor belt, especially the herringbone pattern part. If there is excessive wear, it should be handled in time.

Tension adjustment

Check the tension of the conveyor belt regularly. Excessive tension can easily lead to increased wear and even breakage of the conveyor belt; too little tension may cause the conveyor belt to slip. According to the operation of the equipment and the state of the conveyor belt, adjust the tension device reasonably.

Component inspection

Regularly check the operation of the roller and the roller. The wear of the roller will affect the smooth operation of the conveyor belt. If the roller is stuck or damaged, it will cause uneven force on the conveyor belt. If the problem parts are found, they should be replaced in time.

By mastering these installation and maintenance skills, the service life of the herringbone conveyor belt can be effectively extended, production efficiency can be improved, and equipment operation costs can be reduced.

herringbone conveyor belt

Previous:

Next article

Previous:

Next article

Latest News

Product

About Us

We specialize in producing heavy-duty EP nylon conveyor belts, steel cord conveyor belts, corrugated rib conveyor belts, bucket elevator conveyor belts, herringbone conveyor belts, ring conveyor belts, etc. As a Chinese conveyor belt manufacturer, supplier and exporter, we focus on providing customers with high-quality conveyor belts and better services.

Baoding Fangnuo Rubber Products Manufacturing Co., Ltd.

Copyright Baoding Fangnuo Rubber Products Manufacturing Co., Ltd., All rights reserved